Laboratoire imwe ya extruder ikoresha umugozi uzunguruka kugirango ushonge, uvange, kandi ushushanye polymers imbere muri barri ishyushye. Abashakashatsi bishingikiriza kuriyashizwemo umugozi umwe, imashini imwe, naimashini itagira amazikugera kubintu byiza bivanze kandi bifite umutekano, gutunganya neza. Ubushakashatsi bwerekana koumuvuduko n'ubushyuhebigira ingaruka nziza kubicuruzwa n'umutekano.

Ibyingenzi byingenzi bigize umugozi umwe

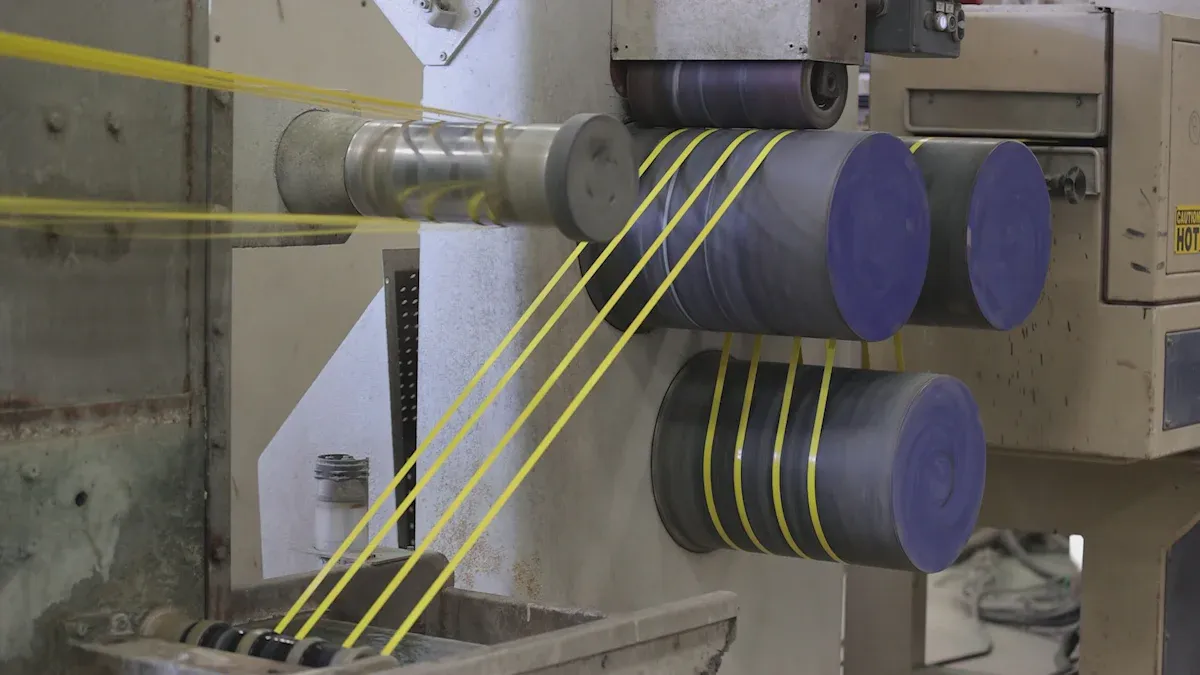

Umuyoboro

Umugozini umutima wa screw imwe extruder. Irazunguruka imbere muri barrale kandi yimura polymer imbere. Imiyoboro irashonga, ikavanga, kandi igasunika ibikoresho bigana ku rupfu. Igishushanyo mbonera, harimo diameter, uburebure bwa diametre, hamwe na compression yo kugereranya, bigira ingaruka kuburyo polymer ishonga kandi ikavanga. Imashini yateguwe neza itezimbere igipimo cyo gushonga no gukora neza. Grooves kuri screw cyangwa barrale irashobora kongera umuvuduko wo gushonga kandi igafasha kugenzura inzira. Umuvuduko wa screw nawo uhindura ingano yo kuvanga nubushyuhe butangwa.

Impanuro: Guhindura umuvuduko wa screw birashobora gufasha kugenzura ubushyuhe bwashonze nubwiza bwibicuruzwa.

Ingunguru

Ingunguruizengurutse umugozi kandi ifata polymer uko igenda. Barrale ifite ahantu h'ubushyuhe butandukanye. Buri zone irashobora gushyirwaho ubushyuhe bwihariye kugirango ifashe gushonga polymer neza. Kurugero, zone yambere irashobora kuba ikonje kugirango ifashe kwimura polymer ikomeye, mugihe nyuma zone zishyushye gushonga ibikoresho. Kugenzura ubushyuhe bukwiye muri barrale ningirakamaro mugutemba neza nubwiza bwibicuruzwa.Thermocouples ipima ubushyuhe imbere muri barrielkugirango inzira ikomeze.

- Igipimo cy'ubushyuhe bwa barrel giterwa n'ubwoko bwa polymer nigishushanyo mbonera.

- Ibisohokayandikiro bigezweho akenshi bifite ahantu h'ubushyuhe butatu cyangwa burenga.

- Igice cyo kugaburira kigomba kuba gishyushye ariko ntigishyushye cyane kugirango wirinde gufata ibintu.

Sisitemu

Sisitemu yo gushyushya ikomeza ingunguru ku bushyuhe bukwiye. Ubushyuhe bushyirwa kumurongo kandi bugenzurwa na sensor. Sisitemu irashobora guhindura buri karere kugirango ihuze ibikenewe na polymer. Kugenzura neza ubushyuhe bifasha kwirinda ibibazo nko gutwika ibintu cyangwa gushonga kutaringaniye. Sisitemu yo gushyushya ikorana na sisitemu yo kugenzura kugirango inzira igire umutekano kandi neza.

Gupfa

Gupfa gukora polymer yashonze mugihe isize umugozi umwe. Igishushanyo mbonera kigira ingaruka kumiterere yanyuma yibicuruzwa, hejuru, nubunini. Urupfu rwiza rutanga neza, ndetse rutemba kandi rufasha gukora ibicuruzwa bifite ibipimo bifatika. Urupfu rugomba guhangana nubushyuhe bukwiye nigitutu kugirango wirinde inenge. Imihindagurikire yubushyuhe cyangwa urujya n'uruza birashobora guhindura ubuziranenge bwibicuruzwa.

- Umuvuduko umwe hamwe nigitutu gito cyo kugabanuka kurupfu ni ngombwa kubwiza.

- Gupfa umuyoboro wa geometrie no kuringaniza bigira ingaruka kumiterere yibicuruzwa.

Sisitemu yo kugenzura

Sisitemu yo kugenzura ikora imikorere imwe ya screw extruder. Ikurikirana ubushyuhe, umuvuduko, umuvuduko wa screw, nigipimo cyibiryo. Abakoresha bakoresha sisitemu yo kugenzura gushiraho no guhindura ibipimo byimikorere. Igenzura-nyaryo rifasha gukomeza inzira ihamye kandi itekanye. Sisitemu yo kugenzura irashobora kandi kubika resept za polymers zitandukanye, byoroshye gusubiramo neza gutsinda.

Ubwoko bwa Extrew imwe ya Extruder yo gukoresha Laboratoire

Igenamiterere rya laboratoire risaba ubwoko butandukanye bwa extruders kugirango uhuze ibyifuzo byubushakashatsi. Buri bwoko butanga ibintu byihariye nibyiza byo gutunganya polymer.

Gukodesha Umuyoboro umwe

Umuyoboro umwe washyizwe ahagaragara ukoresha aibyiciro bibiri. Igishushanyo kigabanya torque nimbaraga zingufu zikenewe mugihe gikomeza ibisohoka n'umuvuduko wa screw. Sisitemu yo guhumeka ikuraho ubushuhe na gaze muri polymer yashonga. Iyi ntambwe ningirakamaro mugutunganya plastike ikurura amazi. Kuraho ibyo bihindagurika birinda inenge nka splay hamwe nubushobozi bwimashini. Icyambu cya ventre gikora munsi yicyuho, gifasha gutesha agaciro kugabanya umuvuduko. Imiyoboro y'ibyiciro bibiri nayo itezimbere kuvanga mugukanda no gusibanganya plastike. Iyi nzira irema gushonga cyane. Abakoresha bagomba kuringaniza ibisohoka hagati yibyiciro byombi kugirango birinde kwiyongera cyangwa umwuzure. Ibiranga bituma imashini imwe ya screw ikora neza kandi yizewe muri laboratoire.

Icyitonderwa: Ibisohoka bihamye hamwe ningufu zo hasi zikoresha gushiraho ibyuma bitandukanya mubushakashatsi.

Imashini imwe

Imashini imwe ya screw itwikiriye ibintu byinshi byo gushonga, kuvanga, no gukora polymers. Izi mashini zitanga igishushanyo cyoroshye kandi cyoroshye gukora. Abashakashatsi barashobora kugenzura ubwogero n'ubushyuhe neza, bifasha muburyo bwa polymer hamwe nibikorwa byo gukuramo. Imashini imwe ya screw ikora neza mugukora tubing, firime, nibindi bicuruzwa byoroshye. Ziza mubunini butandukanye no muburyo bwo guhuza ibikenewe mubushakashatsi butandukanye.

| Ubwoko bwa Extruder | Ibyingenzi byingenzi nibyiza | Porogaramu isanzwe kandi ikwiranye |

|---|---|---|

| Umuyoboro umwe | Igishushanyo cyoroshye, kugenzura neza, imikorere yoroshye | Igituba, firime, shingiro rya polymer |

| Twin Screw Extruders | Kuvanga birenze, guhuza, guhuza intera | Guteranya, ibikoresho bigoye, imiti |

| Miniature / Micro Extruders | Ingano ntoya, ihendutse, yizewe | R&D, prototyping, ibikoresho bike byintangarugero |

Imashini itagira amazi

Imashini ya granulator idafite amazi ihindura ibikoresho bya pulasitike muri granules idakoresheje amazi. Iri koranabuhanga ritezimbere ingufu kandi rigabanya ingaruka zidukikije. Inzira ituma granules yumye kandi isukuye, bigirira akamaro izindi ntambwe zo gutunganya. Imashini zitagira amazi zitagira amazi zikoresha ubwoko bwinshi bwa plastike. Bafasha abashakashatsi gukora granules nziza yo gupima no kwiteza imbere.

Intambwe-ku-ntambwe Polymer yo gukuramo

Kugaburira ibikoresho bya Polymer

Igikorwa cyo gukuramo gitangirana no kugaburira ibikoresho bya polymer mbisi. Hopper yemeza no gukwirakwiza kandi ikabuza guhagarika, ifasha kugumya kwinjiza neza. Imiyoboro iri imbere muri barrale itangira kuzunguruka, ikurura polymer pellet cyangwa ifu imbere. Igishushanyo cya screw, harimo diameter yacyo hamwe nuburebure bwa diametre, bigira uruhare runini muburyo ibintu bigenda neza. Sisitemu yo kugenzura yemerera abashoramari guhindura umuvuduko wa screw nigipimo cyibiryo, bifasha guhuza neza inzira ya polymers zitandukanye.

- Kugaburira ibyokurya byagenewe gukumira inzitizi no kugaburira neza.

- Imiyoboro iratanga, igahagarika, igatangira gushyushya polymer.

- Kugenzura ubushyuhe muri barrale bifasha guhuza inzira yo gushonga.

Ubushakashatsi bwambere bwerekanye ko kugenzura umuvuduko nubushyuhe bigira ingaruka kuburyo polymer igaburira kandi ishonga. Laboratoire zigezweho zikoresha igenzura rigezweho kugirango ukomeze kugaburira neza kandi bihamye.

Gushonga na plastike

Mugihe polymer igenda kuri barriel, yinjira ahantu hashyushye. Ubushyuhe muri buri karere bwiyongera buhoro buhoro, bigatuma polymer yoroshye kandi ishonga. Kuzenguruka kwa screw hamwe nubushyuhe bwa barrile bifatanyiriza hamwe guhuza plastike, bigahinduka misa imwe yashongeshejwe. Sensor zashyizwe kumurongo zikurikirana ubushyuhe nigitutu kugirango polymer ishonga muburyo bwiza bwo gutunganya.

| Parameter | Ibisobanuro |

|---|---|

| Gushonga Ubushyuhe | Ugomba kuguma murwego rwo gutunganya polymer kubisubizo byiza. |

| Umuvuduko uri hejuru yumurongo | Yerekana gushonga ubuziranenge no gutezimbere. |

| Imihindagurikire y'ingutu | Gukurikiranwa kugirango umenye ibibazo byose bishonga cyangwa bitemba. |

| Imihindagurikire yubushyuhe | Kurikirana kugirango ushushe ndetse ushushe kandi wirinde inenge. |

| Impamyabumenyi yo gushonga | Kugenzurwa muburyo bugaragara cyangwa mugupima firime yakuwe kugirango bisobanuke kandi bihwanye. |

| Igipimo cyerekana imikorere | Huza ibi bintu kugirango ugereranye ubwiza bwashonga kuva mubukene (0) kugeza kuri byiza (1). |

Kugenzura neza ubushyuhe nigitutu bifasha mukurinda kwangirika kandi bigatuma gushonga guhoraho. Igenzura-nyaryo hamwe na sensor igezweho hamwe na tekinoroji ya spekitroscopi itanga amakuru ahoraho, yemerera abashakashatsi guhindura igenamiterere nkuko bikenewe.

Kuvanga no gutanga

Iyo bimaze gushonga, polymer igomba kuvangwa neza kugirango habeho uburinganire. Igishushanyo cya screw, harimo ibintu nkibice bya bariyeri cyangwa kuvanga uturere, bifasha guhuza ibikoresho no gukuraho ibice byose bisigaye. Mugihe umugozi uzunguruka, usunika polymer ushongeshejwe imbere, ukawugeza ku rupfu.

Abashakashatsi bakoresha ibikoresho byateye imbere hamweIcyitegererezo cy'icyitegererezo hamwe na optique ya optiquekwiga uburyo ibikoresho bivanze neza. Mugutera inshinge no gupima uko zikwirakwira, barashobora kubona uburyo umuvuduko wa screw na geometrie bigira ingaruka kuvanga. Umuvuduko mwinshi urashobora rimwe na rimwe gusiga ibice bikomeye, ariko ibishushanyo bidasanzwe bya screw bitezimbere kuvanga no gukumira iki kibazo.Ibyuma byerekana ingufu kuri barrielbapima uburyo polymer yimuka neza, ifasha abakoresha gukora neza inzira.

Guhindura Urupfu

Polimeri yashongeshejwe igera ku rupfu, ikabikora muburyo bwifuzwa. Igishushanyo cy'urupfu kigena ingano y'ibicuruzwa bya nyuma n'ubuziranenge bw'ubuso. Ba injeniyeri bakoresha amashusho ya mudasobwa hamwe nisesengura ryibintu bitagira ingano kugirango bashushanye bipfa gutanga imiterere nyayo kandi bigabanya inenge. Batezimbere kandi umuyoboro wa geometrie kugirango uhuze umuvuduko kandi ugabanye itandukaniro rya molekulari, bishobora kugira ingaruka kubicuruzwa.

| Ibimenyetso | Ibisobanuro |

|---|---|

| Isesengura ryibanze | Byakoreshejwe mukwiga gutemba no gushushanya neza mugupfa. |

| Igishushanyo mbonera | Kugabanya amakosa no kunoza neza geometrike. |

| Kwemeza Ubushakashatsi | Yemeza kugenzura neza ibipimo byibicuruzwa. |

| Kwigana Umubare | Abahanuzi bapfa kubyimba no kugenda kwimbere kubisubizo byiza. |

| Kugenzura Icyerekezo cya Molecular | Impirimbanyi zitemba kugirango wirinde kurambura kutaringaniye no guhindura imiterere. |

Kugenzura neza ibyapfuye nibikoresho byo hasi byemeza ko ibicuruzwa biva iUmuyoboro umwehamwe nuburyo bukwiye.

Gukonja no Gukomera

Nyuma yo gushiraho, polymer ishyushye isohoka ipfa ikinjira mugice cyo gukonja. Gukonjesha gushimangira polymer, gufunga muburyo bwa nyuma nimiterere. Igipimo cyo gukonjesha giterwa nubushyuhe bwo gusohora, imiterere y'ibidukikije, n'umuvuduko ibicuruzwa bigenda muri zone ikonje.

| Parameter / Aspect | Indorerezi / Ibisubizo |

|---|---|

| Ubushyuhe bukabije | Polymer yakuwe kuri 100 ° C. |

| Ubushyuhe bwibidukikije | Yagumishijwe hafi 20 ° C mugihe cyubushakashatsi |

| Ubukonje bukabije | Hafi ya 72 ° C. |

| Ingaruka z'umuvuduko | Umuvuduko wo hasi utinda gukonja no kongera igihe cyo gukomera |

| Imyitwarire ikonje | Igipimo ntarengwa kigabanuka uko umuvuduko ugabanuka; impinga ihinduka umwanya muremure |

| Ingaruka nyinshi | Nyuma ibice birashobora gushyushya ibyambere, bigatezimbere |

Kubungabunga ahantu hakonje mubushyuhe buke, akenshi muri ± 2 ° C, bifasha kwemeza ubuziranenge bwibicuruzwa. Gukonjesha neza birinda kurwana kandi byemeza ko polymer ikomera neza.

Porogaramu ya Extruder imwe imwe mubushakashatsi bwa Polymer

Gutegura Ibikoresho no Kwipimisha

Abashakashatsi bakoresha laboratoire ya laboratoire kugirango batezimbere kandi bagerageze kuvanga polymer nshya. Inyigisho zifatizo hamwe na patenti bisobanura uburyoigishushanyo mbonerano gucunga ubushyuhe bitezimbere gushonga no kuvanga. Iterambere rifasha abahanga gukora ibikoresho bishya bifite imiterere yihariye. Kurugero, ubushobozi buke bwa extruder yubatswe hamwe nibikoresho byaho byerekanaga imikorere ikomeye mubikorwa bya laboratoire. Yatunganije kugeza kuri kg 13 kumasaha kandi igabanya ibice bidakenewe mubicuruzwa byanyuma. Ibisubizo byemeza ko abakora laboratoire bashyigikira udushya no kugenzura ubuziranenge mugutegura ibintu.

| Parameter | Agaciro / Ibisubizo |

|---|---|

| Ibicuruzwa | 13.0 kg / h |

| Umuvuduko | 200 rpm |

| Diameter | Mm 40 |

| Ikigereranyo cyo Kwaguka | 1.82-22.98 |

| Kugabanya Kugerageza Kugerageza | 61.07% –87.93% |

Gukwirakwiza inzira

Laboratoire ya laboratoire ifasha abahanga kubona inzira nziza yimikorere ya polymers zitandukanye. Ubushakashatsi bwakozwe bwerekana kogukoresha ingufu biterwa n'umuvuduko wa screw nibintu bifatika. Mu kwandika ingufu za moteri no guhindura igenamiterere, abashakashatsi barashobora kuzamura ingufu zingirakamaro hamwe nibicuruzwa byiza. Ubushakashatsi bwerekana kandi ko guhindukaumuvudukono kongeramo ibintu bimwe bishobora kunoza uburyo polymers ivanga kandi itemba. Ibyavuye mu bushakashatsi bifasha amatsinda gushyiraho inzira zizewe, zikora neza, kandi zisubirwamo haba mubushakashatsi no kubyara umusaruro.

Impanuro: Guhindura umuvuduko wubushyuhe nubushyuhe birashobora kuringaniza imikoreshereze yingufu no kuzamura ubwiza bwibicuruzwa.

Gitoya-Ibicuruzwa Prototyping

Abashinzwe laboratoire borohereza gukora uduce duto twibicuruzwa bishya. Amakipe arashobora kugenzura ubushyuhe, umuvuduko, na screw umuvuduko kubisubizo byizewe. Ubu buryo buzigama amafaranga kandi byihutisha iterambere. Abashakashatsi barashobora kugerageza vuba ibitekerezo bishya no gupima ibitekerezo byatsinze. Isohora ryoroheje naryo ryemerera impinduka zoroshye mubintu cyangwa mubishushanyo. Iterambere mu buryo bwikora no kugenzura igihe nyacyo kurushaho kunoza imikorere no kugabanya imyanda.

- Kugenzura neza ibipimo byimikorere

- Ikiguzi-cyiza kandi cyihuse prototyping

- Guhindura byoroshye ibikoresho bitandukanye

- Kuzamura ibicuruzwa byiza hamwe nuburinganire

Inama zikorwa no gukemura ibibazo bya Extruder imwe

Gushiraho Extruder

Gushiraho neza bituma ibikorwa byizewe kandi byongerera ibikoresho ubuzima. Abatekinisiye bakurikiza ibiintambwe zo gukora neza:

- Shyiramo imigozimumwanya wabo wambere kandi ugerageze imigozi mishya kumuvuduko muke mbere yo gukora byuzuye.

- Hindurakugenzura ubushyuheibikoresho buri gihe kugirango bihindurwe neza.

- Koresha amazi yatoboye mu kigega gikonjesha kugirango wirinde kwipimisha no kugenzura urugero rwamazi kenshi.

- Kugenzura solenoid valve na coil, usimbuze ibice byose bidakwiye.

- Umutekano uhuza buri munsi kandi urebe ko ubushyuhe bwo gushyushya hamwe na solenoid valve ikora neza.

- Sukura ibigega bya vacuum n'ibyumba bisohora; gusimbuza impeta zambarwa zambarwa nkuko bikenewe.

- Reba kuri moteri ya DC kandi urinde ingese.

- Shyushya buhoro buhoro mugihe cyo gutangira kandi wongere umuvuduko wa screw buhoro.

- Gusiga amavuta yimuka kandi ugahambira buri gihe.

- Kubika igihe kirekire, koresha amavuta arwanya ingese kandi ubike imigozi neza.

Inama: Gukurikiza izi ntambwe bifasha kugumana ubuziranenge bwibikoresho no kuramba.

Ibibazo rusange hamwe nibisubizo

Abakoresha barashobora guhura nibibazo byinshi mugihe cyo gukora. Imbonerahamwe ikurikira irerekana ibibazo bisanzwe nibisubizo:

| Icyiciro | Ibibazo Rusange | Impamvu | Ibimenyetso | Ibisubizo |

|---|---|---|---|---|

| Kunanirwa kwa mashini | Umugozi wiziritse | Kwubaka ibikoresho, lube ikennye | Kurenza moteri, urusaku | Isuku, gusiga, kugenzura |

| Kunanirwa kw'amashanyarazi | Kunanirwa na moteri | Ubushyuhe bukabije, umuzunguruko mugufi | Nta gutangira, gushyuha | Kugenzura sisitemu, irinde kurenza urugero |

| Kunanirwa | Guhindura plastike nabi | Umuvuduko muke, temp itariyo | Ubuso bubi, ibituba | Hindura umuvuduko, temp, ibikoresho |

| Ingamba zo kwirinda | Kubungabunga | Kubura isuku, kugenzura | N / A. | Gahunda yo gukora isuku, ubugenzuzi |

Kugenzura no kubungabunga buri gihe birinda ibibazo byinshi. Abakoresha bagomba gukurikiza amabwiriza yintoki mugihe bahinduye extrusion bapfa kugirango birinde amakosa.

Ibitekerezo byumutekano

Laboratoire ya laboratoire ikubiyemo ingaruka nyinshi. Ingamba z'umutekano zirimo:

- Kwambara ibikoresho birinda umuntu nkinkweto z'umutekano hamwe nikirahure.

- Irinde imyenda irekuye hafi yimuka.

- Gutsindira ibikoresho byose byamashanyarazi nabakozi babishoboye.

- Kugumisha hasi hasi no gukoresha urubuga cyangwa imiyoboro kugirango wirinde kunyerera.

- Gushiraho izamu kubice byimuka kugirango urinde amaboko.

- Koresha imirongo itangirira kumutwe aho kugaburira intoki.

Icyitonderwa: Indero ikomeye yumutekano igabanya ibyago byo gutwikwa, guhitanwa n amashanyarazi, no gukomeretsa imashini.

Laboratoire ya laboratoire ishyigikira umutekano utunganijwe nezakugenzura neza ubushyuhe, umuvuduko, n'umuvuduko wa screw. Abashakashatsi bungukirwa n'umusaruro muto, kugabanya imyanda, hamwe na prototyping yihuse. Igishushanyo mbonera gishobora guhindura byihuse no kwihindura. Imyitozo ihamye no kwitondera amakuru arambuye bifasha kugera kubisubizo byizewe no guteza imbere udushya mubushakashatsi bwa polymer.

Ibibazo

Ni ubuhe bwoko bwa polymer bushobora gukora laboratoire imwe ya screw extruder?

A laboratoire imwe ya screw extruderIrashobora gutunganya ibintu byinshi bya termoplastike, harimo polyethylene, polypropilene, polystirene, na PVC. Abashakashatsi bakunze guhitamo ibikoresho bishingiye kubisabwa n'umushinga.

Nigute guhumeka bizamura ubuziranenge bwa polymer?

Venting ikuraho ubushuhena gaze ziva muri polymer zishonga. Iyi ntambwe irinda inenge, nkibibyimba cyangwa ibibanza bidakomeye, kandi itezimbere ibicuruzwa byanyuma.

Nigute abashoramari bagenzura ubushyuhe bwo gukuramo?

Abakoresha bashiraho kandi bagenzura ubushyuhe bwa barrale bakoresheje sisitemu yo kugenzura. Sensors itanga ibitekerezo-nyabyo, itanga ihinduka ryukuri rya polymer ihoraho no gushonga.

Igihe cyo kohereza: Jul-01-2025