PE ntoya ya granulators muri 2025 ikoresha moteri ikora neza, gukora neza, hamwe nigihe cyogukora kugirango igabanye gukoresha ingufu. Abakoresha babona ibisubizo byihuse, nka aKugabanuka 40% mukoresha ingufu kuri toniugereranije na gakondoimashini imwe or yashizwemo umugozi umweSisitemu. Kugarura ubushyuhe bwimyanda nabyo birashigikiraimashini itagira amaziibikorwa.

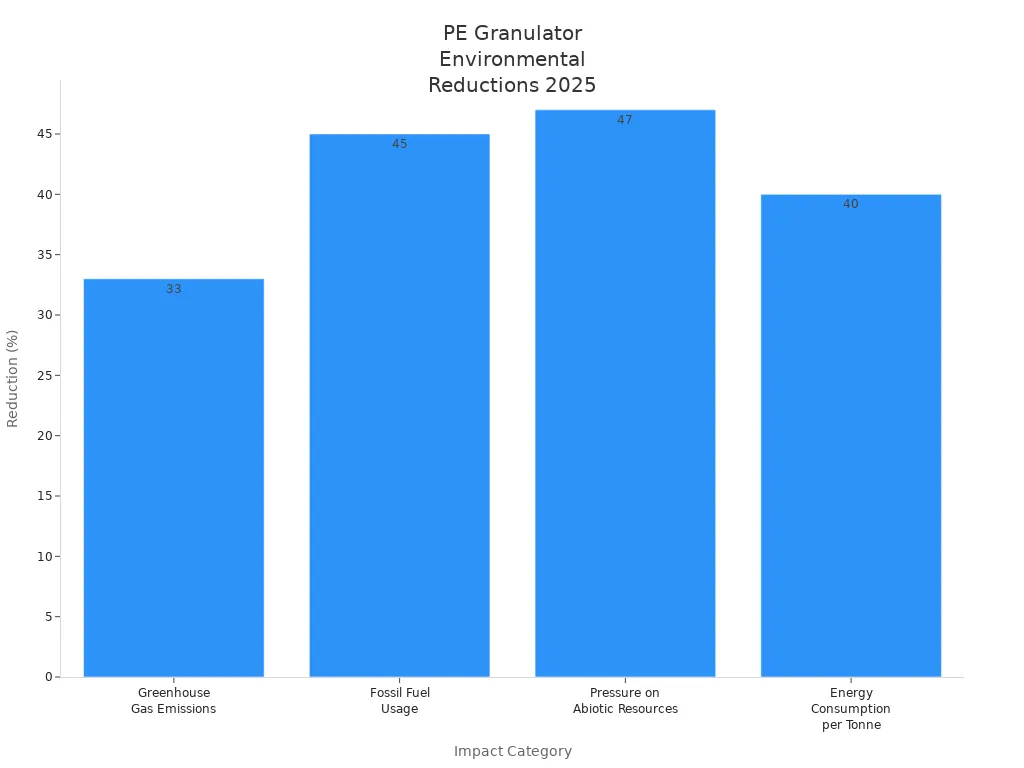

| Ibipimo | Kugabanuka kugerwaho muri 2025 ugereranije nimyaka yashize |

|---|---|

| Kugabanya ibyuka bihumanya ikirere | Kugabanuka 33% |

| Kugabanya ikoreshwa rya peteroli | Kugabanuka 45% |

| Umuvuduko Kubikoresho bya Abiotic | Kugabanuka 47% |

| Gukoresha Ingufu kuri Tonne | Hafi ya 10 kW-h / tonne, 40% ugereranije nibikoresho gakondo |

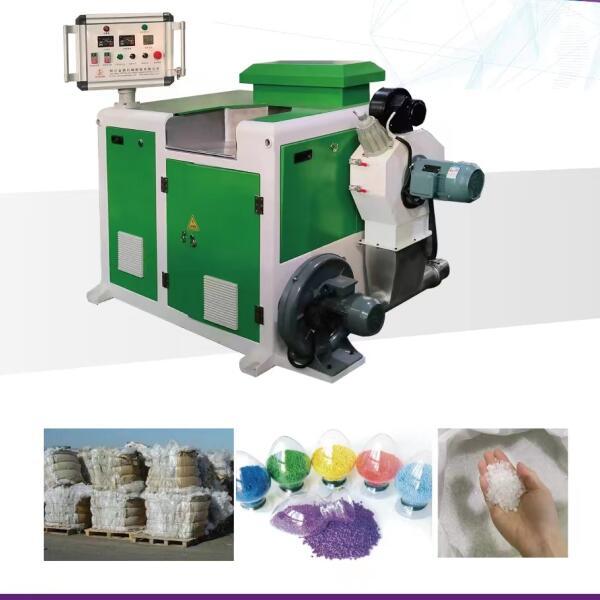

PE Ibidukikije bito byangiza ibidukikije: Ikoranabuhanga rizigama ingufu

Moteri nziza cyane hamwe nibikoresho byohereza

PE ntoya ya granulators muri 2025 yishingikirizamoteri ikora neza hamwe nibikoresho bigezweho byoherezakugera ku kuzigama ingufu zikomeye. Moteri zihindura ingufu z'amashanyarazi imbaraga za mashini hamwe nigihombo gito, byemeza ko ingufu nyinshi zinjiza zitwara inzira ya granulation. Ibikoresho byogukwirakwiza bigezweho byongera imikorere neza mugutezimbere uburyo ingufu ziva kuri moteri zigana gukata no gukuramo ibice. Iyo uhujwe, tekinoroji igabanya gukoresha ingufu muri rusange mugihe ikora. Uku kwishyira hamwe gushiraho ingamba zuzuye zo kuzigama ingufu zishyigikira ikoreshwa ryingufu nke ndetse no gukora neza. Ababikora bungukirwa no kwishyuza amashanyarazi make no kunoza imikorere yibikoresho. Gukoresha moteri ikora neza hamwe nibikoresho byohereza nabyo byongerera igihe cya granulator, bikagabanya ibikenerwa byo kubungabunga no gutaha.

Inama:Kuzamura moteri ikora neza hamwe na sisitemu yohereza bishobora kugabanya gukoresha ingufu kugera kuri 30% ugereranije na moderi zishaje.

Ubwenge bwo Kwiyubaka no Gukwirakwiza Ibikorwa

Ubwenge bwubwenge buhagaze kumurongo wa kijyambere PE ntoya y'ibidukikije. Sisitemu ikoresha igenzura ryubwenge kugirango ikurikirane kandi ihindure ibipimo byingenzi byerekana imikorere nkubushyuhe, umuvuduko wa moteri, hamwe no kunyeganyega. Abakoresha barashobora kwishingikiriza kumiterere nka ecran ya PLC ikora, ituma ihinduka ryubushyuhe n'ubunini bwa pellet. Sensors itahura ibibazo nko gupfa gufunga cyangwa gutwara moteri birenze, kugabanya ibyago byo gutaha bitunguranye.

- Granulator yubwenge igenzura ibipimo byerekana imikorere yo kubungabunga.

- Sisitemu ishingiye kuri AI imenyesha igenamigambi ryo kubungabunga, nk'igihe cyo guhindura ibyuma cyangwa amavuta.

- Ibicu bishingiye ku bicu bifasha gukurikirana kure no kohereza ibyibutsa.

- Amashanyarazi ya kabine ashyigikira guhuza byoroshye nibindi bikoresho.

- Automation igabanya intoki, kuzamura umutekano no kwizerwa.

- Gutunganya neza uburyo bwiza bwo gukora neza, gukora granulation no kugabanya imyanda yingufu.

- Igishushanyo mbonera cyemerera kwihitiramo ibikoresho bitandukanye nibikenerwa mu musaruro.

Uburyo bwo gutezimbere uburyo bukomeza kongera ingufu zingufu. Ibishushanyo mbonera byimashini bihuza gutemagura, gukata, gusohora, no gusunika mubikorwa bimwe bikomeza. Ubu buryo bugabanya umurimo, igihe, no gukoresha ingufu. Uburyo bwo kugaburira buri gihe butuma ibintu bigenda neza, bikarinda igihe kandi bikanoza umusaruro mwiza. Kwiyerekana biranga kugenzura kugaburira imodoka, guhuza imiyoboro ibiri, no guhinduranya-byihuta byihuta byerekana umusaruro neza kandi neza. Moteri ikoresha ingufu, moteri yihuta, hamwe na sisitemu yo gukonjesha igezweho nayo igira uruhare mukugabanya ingufu zikoreshwa.

Kwangiza imyanda no kuyikoresha

Kugarura ubushyuhe bwimyanda byerekana iterambere ryinshi muri PE ntoya y'ibidukikije. Mugihe cyo guhunika, imashini zitanga ubushyuhe nkibicuruzwa. Aho kureka ubu bushyuhe bugahunga, sisitemu zigezweho zifata kandi zikongera. Ikoranabuhanga nka pompe yubushyuhe bwo hejuru hamwe na sisitemu yo kubika ubushyuhe bwihuse ukoresheje ibikoresho byo guhindura ibyiciro (PCMs) bigarura ubushyuhe bwimyanda yo hasi kandi ikazamura kugirango ikoreshwe mugutunganya ibyuka cyangwa gushyushya ikirere. Mu nganda zerekana, sisitemu ya pompe yubushyuhe yagaruye hejuru ya 80% yubushyuhe bwimyanda, bigabanya gushingira kumashanyarazi kugeza munsi ya 20%. Ibi ntabwo bizamura ingufu muri rusange gusa ahubwo binatanga umusaruro ushimishije mubukungu, akenshi wishyura munsi yimyaka itatu. Gukomatanya kubika ubushyuhe hamwe na pompe yubushyuhe bituma ibikorwa bikomeza no guhinduranya imitwaro, kurushaho kugabanya ibiciro byingufu no kugabanya imyuka ihumanya ikirere.

| Ikoranabuhanga | Imikorere | Ingaruka ku Gukoresha Ingufu |

|---|---|---|

| Ubushyuhe bwo hejuru | Kuzamura imyanda yubushyuhe bwo gutunganya | Kugabanya gushyushya amashanyarazi |

| Ububiko Bwatinze Ubushyuhe (PCM) | Kubika no kurekura ubushyuhe nkuko bikenewe | Gushoboza kwimura imitwaro |

| Sisitemu ya Hybrid | Gukomatanya byombi kugirango bikore neza | Igarura 81.1% yubushyuhe |

PE ntoya ya granulators ishyiraho urwego rushya rwo gukoresha ingufu mugutunganya plastike. Iterambere ryabo rizigama ingufu zifasha ababikora kugabanya ibiciro, kuzamura umusaruro, no gushyigikira intego zibidukikije.

Inyungu za PE Ntoya Ibidukikije Granulators muri 2025

Kugabanya ibiciro byo gukora no gukoresha ingufu

Abahinguzi babona kuzigama neza mugihe bakoresheje PE ntoya ya granulators. Moderi ikonjesha ikirere ikuraho amazi, abika amafaranga yo gutunganya amazi no gufata neza ibikoresho. Izi granulator zikoresha ingufu nke ugereranije na sisitemu ikonjesha amazi kubera imiterere yoroshye kandi ikora neza. Kubungabunga biroroha, kandi ibyago byo gusenyuka biturutse kubibazo bya sisitemu y'amazi biragabanuka. Abakora barashobora gukoresha izo mashini ahantu hafite amazi make cyangwa ikirere cyiza, bigatuma umusaruro uhoraho. Gukonjesha kimwe kandi bizamura ubuziranenge bwibicuruzwa kandi bigabanya imyanda.

- Igikorwa gikonjesha ikirere gikuraho ibiciro byamazi no kuyitaho bijyanye.

- Gukoresha ingufu nke bisobanura fagitire ntoya.

- Imiterere yoroshye igabanya ibikenewe byo gusanwa nigihe gito.

- Imikorere ihamye mubidukikije bigoye itanga umusaruro wizewe.

- Ubwiza bwibicuruzwa biganisha ku myanda mike kandi ikora neza.

Ingaruka ku bidukikije no kugabanya ibirenge bya Carbone

PE ntoya ya granulators ifasha ibigo kugabanya ingaruka zibidukikije. Bagabanya ibyuka bihumanya kandigukoresha ingufu, gukora plastike itunganya icyatsi.

| Inyungu ku bidukikije | Ibisobanuro |

|---|---|

| Kugabanya imyuka ya CO2 | Toni 1.5 CO2 yagabanutse kuri toni ya pellet nshya |

| Kugabanya Gukoresha Ingufu | 30% imbaraga nke zikoreshwa na granulator nshya yihuta |

| Kugabanya urusaku | 20dB urwego rwo hasi rwurusaku |

| Kongera gutunganya ibiciro | Gufunga-gusubiramo ibicuruzwa bigabanya gukoresha ibikoresho bibisi |

| Urugero Urugero - Imodoka | Toni 300 za plastiki nshya yazigamye buri mwaka mugutunganya imyanda ya bumper |

| Urugero Urugero - Ubuhinzi | 85% igipimo cyo guhindura cyagezweho nabahinzi babahinde bakoresheje pelletiseri nto |

Izi mashini kandi zunganira ubukungu bwizunguruka zihindura imyanda ya plastike mo granules ikoreshwa. Iyi nzira igabanya imyanda kandi ikiza umutungo kamere.

Kubahiriza no guhuza n'imihindagurikire y'inganda

PE ntoya ya granulators ifasha ibigo kubahiriza amategeko akomeye y’ibidukikije mu turere twinshi. Imashini zishyigikira gutunganya no kugabanya imyanda, ihuza na gahunda za leta kumyanda ya zeru. Ingero nyinshi zujuje ubuziranenge mpuzamahanga nka ISCC PLUS, ikurikirana imikoreshereze y’amatungo arambye kandi ikemeza kubahiriza intego z’imibereho n’ibidukikije. Igishushanyo cyabo cyoroshye gihuza ibikorwa binini na bito, bifasha ubucuruzi kumenyera guhindura amategeko. Iterambere ryambere kandiibintu bizigama ingufukoroshya gukurikiza amategeko mashya yerekeye imyuka n’urusaku. Amasosiyete yo muri Amerika ya Ruguru hamwe n’Uburayi akoresha izo granulator kugirango ashyigikire intego z’ubukungu buzenguruka kandi yujuje ubuziranenge bw’ibanze ndetse n’isi yose.

PE ntoya ya granulators yibidukikije igera kubikorwa byingufu nyinshi ukoresheje ibishushanyo byihuta, imiterere yihariye, hamwe nubuhanga buhanitse bwo gutunganya. Izi mashini zifasha inganda kugabanya ibiciro, kugabanya imyanda, no gushyigikira ubukungu bwizunguruka. Amasosiyete ahitamo izo granulators atezimbere kuramba, yujuje amabwiriza, kandi agashiraho ejo hazaza heza.

Ibibazo

Nigute PE ntoya ya granulator yibidukikije ibika ingufu?

Granulator ikoresha moteri ikora neza kandi ikora neza. Ibi biranga kugabanya amashanyarazi no kugabanya imyanda mugihe cyo gukora granule.

Inama:Kubungabunga buri gihe bifasha kugumya ingufu hejuru.

Granulator irashobora gukora ubwoko butandukanye bwimyanda ya plastike?

Yego. Imashini ishyigikira ibikoresho bitandukanye bya plastiki. Abakoresha barashobora guhindura igenamiterere kuri buri bwoko, bakemeza neza ko bisohoka hamwe nibisohoka byiza.

Ni ubuhe buryo bwo gufata imashini bukenera?

Abakoresha bagomba kugenzura moteri, kuyungurura, no kugenzura ibyuma bikata buri gihe. Igenzura ryoroshye nibice bya modular bituma gahunda yo kubungabunga byihuse kandi byoroshye.

Igihe cyo kohereza: Nyakanga-17-2025