Ndabona ukoUmuyoboro umweguhindura plastike. Iyo nkoresheje ingunguru imwe ya barrique yo gutunganya granulation, mbona neza gushonga neza, kuvanga neza, no kwambara bike. MyIbikoresho bya plastiki byo gusubiramo plastikiikora neza. Hamwe n'ubushyuhe bwuzuye n'umuvuduko wa screw, myExtruder Kuri Plastikeigera kumusaruro mwinshi hamwe na pellet nziza.

- Gushonga

- Umuvuduko

- Ubushyuhe bwa barriel

- Gucunga impungenge

Inzira Zingenzi Zitwara neza

Gutezimbere gushonga

Iyo nkoresheje ibicuruzwa byanjye bisubirwamo, nibanda ku gushonga kimwe. Gushonga homogenisation bivanga kuvanga plastike neza uko ishonga, buri pellet rero ifite ubuziranenge bumwe. Nabyizekugenzura ubushyuhe bwo gushonga no gutembani ngombwa. Ubushakashatsi kuri plastike nka nylon na polypropilene bwerekana ko iyo nkomeje gushonga umwenda, mbona pellet nziza. Niba gushonga bidahuye, plastiki yongeye gukoreshwa irashobora gucika intege cyangwa gucika intege.

Ndabona itandukaniro mubwiza bwa pellet iyo nkoresheje ingunguru imwe ya screw yagenewe kuvanga neza. Kurugero, ubushakashatsi kuri melt-state shear homogenisation yerekana ko kuvanga-shear nyinshi kuvanga muri barrele imwe ya screw bitezimbere uburinganire bwumubiri nubushyuhe bwa plastiki yongeye gukoreshwa. Iyi nzira igabanya umwanda kandi ihindura imiterere ya polymer muburyo bufasha hamwe nintambwe zongera gukoreshwa. Ndabona ko pellet yanjye yongeye gukoreshwa ifite inenge nke kandi imikorere myiza mugihe gushonga ari kimwe.

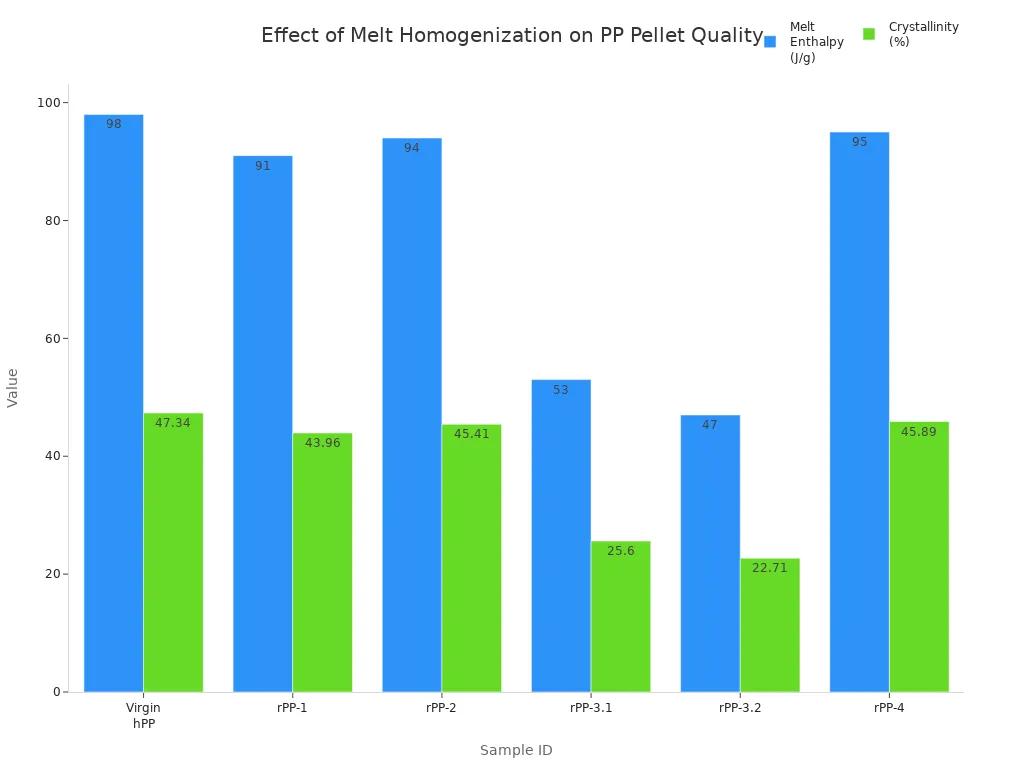

Imibare isubiza inyuma ibyo mbona mu iduka ryanjye. Iyo ngereranije ingero za polypropilene zisubirwamo, abafite kristu yo hejuru kandi bashonga ishyaka ryinshi kandi bagakora byinshi nka plastiki yisugi. Dore imbonerahamwe yerekana uburyo ibintu bitandukanye byo gutunganya bigira ingaruka kumiterere ya pellet:

| Icyitegererezo | Gushonga Enthalpy (J / g) | Crystallinity (%) |

|---|---|---|

| Isugi homopolymer PP (hPP) | 98 | 47.34 |

| PP-1 yongeye gukoreshwa (rPP-1) | 91 | 43.96 |

| PP-2 yongeye gukoreshwa (rPP-2) | 94 | 45.41 |

| Gusubiramo PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Gusubiramo PP-3.2 (rPP-3.2) | 47 | 22.71 |

| PP-4 yongeye gukoreshwa (rPP-4) | 95 | 45.89 |

Buri gihe mpora mbona ibisubizo nka rPP-1, rPP-2, na rPP-4, byegereye inkumi PP. Indangagaciro zo hasi, nka rPP-3.1 na rPP-3.2, mbwira gushonga ntabwo byari bivanze neza cyangwa byari bifite umwanda.

Iyo ngenzuye gushonga no kuvanga, mbona kandi ibikoresho bya mehaniki byiza mubicuruzwa byanyuma. Pelletes zanjye zongeye gukoreshwa zirambuye kandi zifata hafi kimwe na plastiki nshya, bivuze ko nshobora kuzikoresha mubisabwa byinshi.

Gukoresha neza Geometrie

Imiterere nigishushanyo cya screw imbere muri extruder yanjye ikora itandukaniro rinini. Nagerageje imigozi itandukanye ya geometrie mbona uburyo bigira ingaruka kumikoreshereze yingufu, gushonga ubwiza, nibisohoka. Iyo nkoresheje screw hamwe na geometrie iburyo, mbona byinshi bivanze kandi byinjira cyane. Nkoresha kandi imbaraga nke, zizigama amafaranga kandi zigabanya kwambara kubikoresho byanjye.

- Gore geometrie igira ingaruka zingufu nkeneye nuburyo ubushyuhe bwashushe bugumaho.

- Kongera umuvuduko wa screw birashobora kugabanya gukoresha ingufu, ariko igishushanyo cya screw kigomba guhuza nibikoresho.

- Inzitizi ya bariyeri hamwe no kuvanga ibintu bifasha kugumana ubushyuhe bwashushe ndetse no kunoza kuvanga.

- Ibishushanyo bimwe bya screw reka nkore extruder byihuse ntataye ubuziranenge.

- Iburyo bwiburyo bwa geometrie buringaniza ingufu hamwe nibisohoka byinshi hamwe nubwiza bwiza bwo gushonga.

Nabonye ko inzitizi za bariyeri, zitandukanya plastike ikomeye kandi yashonze, binyemerera kwiruka kumuvuduko mwinshi no kubona ibisohoka byinshi. Ariko, nkeneye kureba ibyinjira kugirango nkomeze gushonga. Kuvanga ibintu nkibice bya Maddock shear bimpa homogenisation nziza, bivuze inenge nke muri pellet yanjye.

Dore kugereranya byihuse ubwoko bwa screw n'ingaruka zabyo:

| Genda Geometrie | Kuvanga guhuza (Guhuza ibitsina) | Ibicuruzwa | Inyandiko |

|---|---|---|---|

| Inzitizi | Nibyiza kumurongo mwinshi, ukeneye kugenzura neza | Hejuru | Ibyiza kumatsinda manini, reba kuvanga kutaringaniye kumuvuduko mwinshi |

| Imirongo itatu | Birahamye, ariko byinjira byinjira | Guciriritse | Nibyiza kubyara umusaruro uhamye, ntabwo byoroshye |

| Kuvanga Ibintu | Guhuza ubutunzi bwiza | Biratandukanye | Maddock shear itanga kuvanga neza, cyane cyane kuri plastiki zikomeye |

Buri gihe mpitamo screw geometrie ihuye na plastiki ndimo gusubiramo. Ubu buryo, mbona impirimbanyi nziza yumuvuduko, ubwiza, nimbaraga zo gukoresha.

Ibikoresho bya Barrel bigezweho

Ibikoresho bya screw barrel bifite akamaro nkibishushanyo byayo. Nishingikirije kuri barrale ikozwe mubyuma byujuje ubuziranenge nka 38CrMoAl, itanga imbaraga nubukomere. Iyo nkoresheje ingunguru zifite ubuso bwa nitride, mbona gusimbuka gukomeye mubukomere. Ibi bivuze ko ibikoresho byanjye bimara igihe kirekire, nubwo ntunganya plastike yangiza cyangwa yanduye.

- Amashanyarazi avanze nka 38CrMoAlA na AISI 4140 ampa kuramba nkeneye.

- Ifu ya metallurgie ibyuma itanga no kwambara neza no kurwanya ruswa.

- Kuvura Nitriding byongera ubukana hejuru, akenshi bigera kuri HV900 cyangwa birenga.

- Bimetallic coatings, nka tungsten karbide, irinda ibyuzuza ibintu.

- Isahani ya Chromium yongeramo urundi rwego rwo kwirinda ingese no kwambara.

Nabonye ko iyo nkoresheje ingunguru hamwe nibikoresho bigezweho hamwe na coatings, nkoresha igihe gito namafaranga mukubungabunga. Extruder yanjye ikora igihe kirekire hagati yigihe cya serivisi, kandi ntabwo ngomba guhangayikishwa cyane no gusenyuka. Uku kwizerwa kureka nkibanda kubyara umusaruro mwiza wo mu rwego rwo hejuru.

Inama:Buri gihe uhuze naibikoresho bya barraleku bwoko bwa plastiki ninyongera utunganya. Ibikoresho bikaze hamwe nigitambaro byishyura mugihe ukoresheje imyanda ya plastike yangiza cyangwa ivanze.

Muguhuza uburyo bwiza bwo gushonga homogenisation, optimiz ya screw geometrie, hamwe nibikoresho bya barriel bigezweho, ndagera kubikorwa byiza nibisubizo byiza mubikorwa byanjye byo gutunganya plastike. Ubu buryo bukorera hamwe kugirango butange ubuziranenge buhoraho, umusaruro mwinshi, nigiciro gito.

Gukemura Ibibazo Bisanzwe byo Gusubiramo

Kurwanya kwanduza no kugaburira ibintu bitandukanye

Iyo nkoze ibikorwa byanjye byo gutunganya, mpura nibiryo bitateganijwe buri munsi. Ibyiciro bimwe birimo plastiki isukuye, imwe. Abandi bahageze bavanze n'umwanda, ibyuma, cyangwa ubuhehere. Nzi ko uduce duto duto twa regrind dufite ubucucike buri hasi kurenza pelleti yisugi. Ibi bigabanya ibicuruzwa kandi bituma extruder yanjye ikora cyane. Niba ntakemuye ibyo bibazo, ndabona ubushyuhe bwo hejuru bwashushe hamwe nubwiza bwa pellet.

Nishingikirije kuri barrique imwe imwe kugirango nkemure ibyo bibazo. Ikibanza cyiza cyo kugaburira geometrie, cyane cyane imifuka yagutse yimifuka, itezimbere kugaburira no gutanga ibintu. Igishushanyo kirinda ibintu guhagarara kandi kigakomeza kugenda neza. Ndabona ko extruder yanjye ikomeza gushonga nubwo natunganya plastike ivanze cyangwa yanduye.

Dore ibibazo nyamukuru mpura nabyo mugutunganya plastike:

- Imiterere idasanzwe kandi nubucucike buke

- Kugabanya ibicuruzwa no gukora neza

- Ubushyuhe bwo hejuru bwo gushonga hamwe na Windows itunganya

- Kwanduza no gutesha agaciro ibintu

- Gutunganya ibintu bitandukanye hamwe na plastiki ivanze

Akabari kanjye kamwe kamfasha gutsinda ibyo bibazo. Ndabona uburyo bwiza bwo kugaburira neza, ibintu bigenda neza, no gukoresha ingufu nke. Iri koranabuhanga rinyemerera gutunganya ibintu byinshi bya plastiki ikoreshwa neza ntatanze ubuziranenge.

Nkunze kugereranya extruders imwe ya screw na extruders. Imashini ya Twin screw itanga kuvanga no gutesha agaciro, ariko birwana numuvuduko mwinshi no kwanduza. Imashini imwe isohoka, nkanjye, ikora filtration-yibanda cyane kandi yihanganira ibyanduye neza. Dore igereranya ryihuse:

| Ikiranga | Umuyoboro umwe | Twin Screw Extruder |

|---|---|---|

| Kuvanga Imikorere | Kuvanga mu rugero, guhuza ubutunzi buke | Kuvanga bihebuje, gukwirakwiza cyane / gukwirakwiza ibikorwa |

| Ubushyuhe bumwe | Ugereranije, ukunda ahantu hashyushye / hakonje | Ikwirakwizwa ryinshi ryubushyuhe bwo gukwirakwiza |

| Ibisohoka bihamye | Nibyiza, birashobora kugira pulsation | Ibisohoka bihoraho, bihamye |

| Guhindura Ibikoresho | Ibyiza kubikoresho bimwe, ibikoresho byisugi | Koresha inyongeramusaruro, kuvanga, ibiryo byanduye |

| Ubushobozi bwo gutesha agaciro | Ntarengwa cyangwa ntayo | Hejuru, hamwe nicyambu cya vacuum na zone zo guhumeka |

| Gukoresha Urubanza | Igipimo gito, isugi yera ABS | Igipimo cyinganda, umwihariko, amabara, yongeye gukoreshwa ABS |

Nahisemo ingunguru imwe ya screw kubushobozi bwabo bwumuvuduko mwinshi no kwihanganira neza umwanda. Iki cyemezo kimfasha kwirinda gusanwa bihenze kandi bituma umurongo wanjye wo gutunganya ibintu ukora neza.

Kugabanya Imyambarire Mubikoresho Byangiza

Amashanyarazi yuzuye kandi yuzuza, nka fibre yibirahure, talc, na karubone ya calcium, bitanga ikibazo gikomeye mubihingwa byanjye. Ibi bikoresho bishaje imigozi na barrale vuba. Nakundaga gusimbuza ibice kenshi, byongeraga igihe cyo hasi nigiciro.

Noneho, nkoresha ingunguru imwe ya screw hamwe nubuvuzi bugezweho bwo kuvura no gutwikira. Barrale yanjye igaragaramo ubuso bwa nitride hamwe na bimetallic alloy layer. Iterambere ryongera imbaraga no kurwanya abrasion. Ndabona itandukaniro rinini muburambe. Ibikoresho byanjye bimara igihe kirekire, niyo ntunganya plastiki zikomeye, zangiza.

Ibintu by'ingenzi bishushanya bimfasha kugabanya kwambara harimo:

- Optimized screw geometrie kugirango wirinde umuvuduko wumuvuduko no gushonga imivurungano

- Guhitamo ibikoresho bidashobora kwambara no kwambara byihariye

- Igishushanyo cyihariye kubikoresho byihariye nibuzuza

- Gutunganya neza kugirango birangire neza

- Porogaramu yo kwigana kugirango isobanukirwe no gukwirakwiza ingufu

Namenye kokwambara cyane bibaho hafi yinzibacyuho, aho ibintu bikomeye hamwe nigitutu kizamuka. Muguhitamo ibikoresho bikwiye hamwe na coatings, I.gabanya kwambara kugeza kuri 60%. Kugenzura buri gihe no kubungabunga uturere twambaye cyane, nko kugaburira no gusohora, komeza extruder yanjye mumiterere yo hejuru.

Inama:Buri gihe mpuza na screw barrel igishushanyo cya plastiki nuzuza nkora. Ubu buryo bwongerera ibikoresho ubuzima kandi butezimbere umusaruro.

Kuzamura inzira ihamye hamwe nibisohoka bihoraho

Gutunganya bihamye nibyingenzi mugukora pellet nziza cyane. Mbere yuko nifashisha tekinoroji imwe ya barriel, narwanaga no gutembera gutemba, gushonga imivurungano, hamwe no gukwirakwiza nabi. Ibi bibazo byatumye umusaruro ugabanuka, ibicuruzwa byiyongera, n’ibiciro by’umurimo.

Hamwe na JT imwe ya screw barrel, ndageraho gushonga gutemba no gusohora bihoraho. Sisitemu yo kugenzura igezweho, harimo sensor na logique igenzura, umfasha kugumana ubushyuhe n'umuvuduko uhoraho. Nkurikiranira hafi imiterere yimikorere kugirango nirinde ihindagurika rishobora guhungabanya imikorere.

Nkoreshabimetallic alloys hamwe no gutwikira nezakuzamura imyambarire no kurwanya ruswa. Ibiranga nibyingenzi mugutunganya plastike yangiza cyangwa yongeye gukoreshwa. Ibikorwa bihamye birinda guhinduka mubicuruzwa no kugabanya imyanda.

Dore intambwe ntera kugirango nkomeze inzira ihamye:

- Kubungabunga buri gihe no gusimbuza mugihe cyimigozi yambarwa hamwe na barrale

- Gukurikirana ubushyuhe nigitutu hamwe na sisitemu yo kugenzura igezweho

- Gukoresha imyirondoro yabugenewe kugirango ushonge neza ubutinganyi no kuvanga

- Kugenzura uturere twambaye cyane kugirango ugabanye igihe gitunguranye

Ubushakashatsi bwerekana ko guhuza umuvuduko wa screw nubushyuhe bwa zone byongera ibicuruzwa kandi bigatezimbere. Umuvuduko wo hasi wongera umuvuduko no kugabanya ingufu za mashini, biganisha kumikorere myiza nibisohoka bihamye. Nanditse inyandiko yerekana umusaruro wiyongereyeho 18% kugeza kuri 36% nyuma yo kunoza igishushanyo mbonera cyanjye.

Icyitonderwa:Kugenzura buri gihe no guhanura byongerera ibikoresho ubuzima kandi bigatezimbere muri rusange ibikorwa byanjye byo gutunganya.

Mugukemura umwanda, kwambara, hamwe nuburyo butajegajega, ingunguru imwe ya screw yamfashije gutanga pellet yizewe, yujuje ubuziranenge. Nujuje ibyifuzo byo gutunganya ibigezweho nizeye kandi neza.

Akabuto kamwe kamwe ko gusubiramo Granulation: Ibisubizo nyabyo-byisi

Kwiyongera kwinjiza no kwiza

Mugihe nahindukiye kuri barrile imwe ya screw yo gutunganya granulation, nabonye imbaraga zigaragara muburyo bwinjira na pellet. Pellet yanjye yongeye gukoreshwa noneho yerekana imbaraga zumukanishi no kurushaho gukorera mu mucyo. Nshobora kugenzura ubunini bwa pellet neza, bumfasha kuzuza ibyifuzo byabakiriya. Igenzura ryambere ryubushyuhe rituma gushonga bigenda neza, bityo nkabona inenge nkeya hamwe na pellet nyinshi.

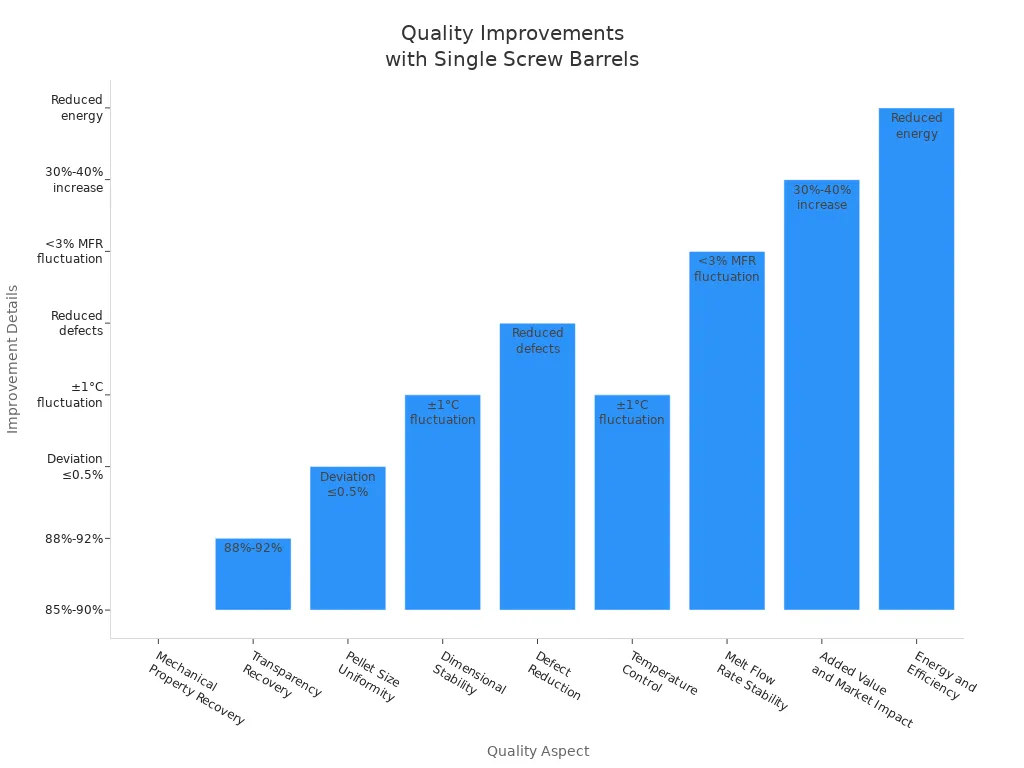

| Ikintu cyiza | Ibisobanuro birambuye |

|---|---|

| Kugarura umutungo wa mashini | 85% -90% igipimo cyo gukira, hejuru cyane ugereranije nibikoresho bisanzwe |

| Kugarura mu mucyo | 88% -92% igipimo cyo gukira |

| Ingano ya Pellet Uburinganire | Ingano yo gutandukana muri 0.5% |

| Ingero zifatika | Ubushyuhe bumwe (± 1 ° C ihindagurika) butuma ituze |

| Kugabanuka neza | Umwanda muke ninenge |

| Kugenzura Ubushyuhe | Igenzura ryibyiciro bitanu, ± 1 ° C ihindagurika |

| Gushonga Igipimo Igipimo gihamye | Imihindagurikire ya MFR iri munsi ya 3% |

| Wongeyeho Agaciro n'ingaruka ku isoko | 30% -40% kwiyongera mubyongerewe agaciro |

| Ingufu nubushobozi | Gukoresha ingufu nke, gukora neza |

Kubungabunga no Hasi

Namenye ko ubuvuzi busanzwe butuma ingunguru imwe ya screw yo gutunganya granulation ikora neza. Nkurikiza gahunda ihamye yo kubungabunga no kugenzura buri cyumweru. Buri gihe nkomeza ubushyuhe hamwe na screw umuvuduko uhoraho kugirango nirinde guhangayikishwa na mashini. Ibiryo bya pulasitiki bisukuye, bitondetse bifasha kwirinda kwangirika kwanduye. Nsukura kandi nsiga amavuta yimuka kugirango mpagarike ingese. Iyo mbonye ibice byambarwa, ndabisimbuza ako kanya. Nahisemo ingunguru ikozwe mu mavuta akomeye hamwe na coat idasanzwe, nka nitriding, kugirango ubuzima bwabo burangire.

- Kugenzura buri cyumwerukomeza ibikoresho byanjye muburyo bwo hejuru.

- Gukosora ubushyuhe hamwe nigitutu cyumuvuduko birinda kwambara.

- Kugaburira ibiryo bigabanya ibyangiritse imbere.

- Gusukura buri gihe no gusiga guhagarika guhagarika.

- Gusimbuza igice cyibikorwa birinda igihe cyo gutungurana.

- Amavuta akomeye hamwe na coatings bituma ingunguru imara igihe kirekire.

Ibimera bikurikiza izi ntambwe byerekana igihe gito kandi nigiciro cyo gusana. Umurongo wanjye wo gusubiramo ubu ukora neza kandi neza.

Inyigo: JT Umuyoboro umwe wa Barrile muri Multi-Plastike

Nashizeho JT imwe ya screw barrel kugirango itunganyirize granulation mu gihingwa cyanjye kugirango nkore plastike zitandukanye nka PE, PP, na PVC. Ibikoresho birwanya kwambara, nka38CrMoAl na tungsten karbide, bongereye ubuzima bwa barrale. Ubu nkoresha amafaranga make yo gusana no gusimbuza. Umurongo wanjye wo kubyara ntukunze guhagarara, nuko nujuje igihe ntarengwa cyo gutanga. Imikorere ihamye ya JT imwe ya screw barrel yo gutunganya granulation yatezimbere umusaruro wanjye kandi igabanya ibiciro byanjye. Ndabona interruption nkeya kandi nzizaubwiza bwa pellet, bimfasha kuguma guhatanira isoko.

Ndabona uburyo ingunguru imwe ya screw ikemura ibibazo byingenzi byo gutunganya. Ubunararibonye bwanjye bwerekana gushonga neza, kuvanga, hamwe nibikorwa bihamye. Hamwe na barrique imwe ya barrique yo gutunganya granulation, ndagera kubikorwa byiza kandi byizewe. Iterambere rishyigikira ibikorwa byogukora isuku, ibiciro biri hasi, kandi bimfasha kuzuza inganda zikura zikenewe kugirango habeho gutunganya amashanyarazi arambye.

Ibibazo

Nibihe plastiki nshobora gutunganya hamwe na JT imwe ya screw?

Nshobora gutunganya plastike nyinshi, harimo PE, PP, PS,PVC, PET, PC, na PA. Barrale ihuza ibikoresho bitandukanye kugirango ikoreshwe neza.

Nigute nagabanya kwambara kuri barriel yanjye?

Nkoresha ingunguru ikozwe mu mavuta akomeye hamwe na nitride cyangwa bimetallic. Gusukura buri gihe hamwe nuburyo bukwiye bimfasha kwagura ubuzima bwa barrale no gukomeza imikorere hejuru.

Kuki gushonga homogenisation bifite akamaro mugutunganya?

Gushonga homogenisation bimpa pellet imwe. Ndabona inenge nke nimbaraga nziza zibicuruzwa. Kuvanga ubudahwema kumfasha kubahiriza ubuziranenge hamwe nibyo abakiriya bakeneye.

Igihe cyo kohereza: Kanama-21-2025