Imashini ibumba inshinge ya plastike ihindura neza plastike mbisi muburyo butomoye. Iyi nzira itanga inyungu zidasanzwe:

- Gukora ibice bigoye hamwe nukuri kurwego rwo hejuru.

- Gutanga ubuziranenge buhoraho no gusubiramo.

- Kugabanya ibiciro byumusaruro mubikorwa binini.

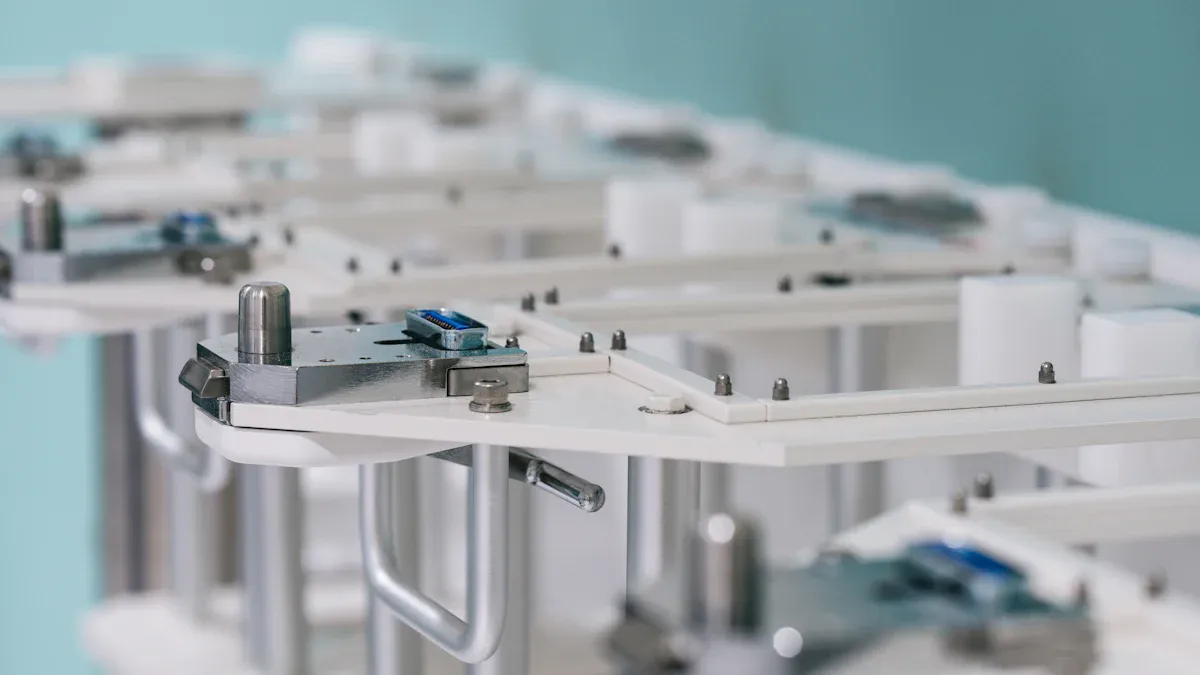

Ibishushanyo mbonera byateye imbere, nkimashini ya Inkingi yo Gutera Imashini naImashini yerekana imashini itera imashini, kuzamura ibikoresho no kunoza imikorere. Byongeye kandiImashini ebyiri yo gutera inshingenaImashini itera inshingekurushaho kunoza imikorere nibisohoka mubikorwa byo gukora.

Igice cyo gutera inshinge muburyo bwo gutera inshinge

Igice cyo gutera inshinge zo mu bwoko bwa Screw Type Injection Molding Machine kigira uruhare runini muguhindura pelletike mbisi zishongeshejwe hanyuma zikayitera mubibumbano. Iki gice kigizwe nibice bitatu byibanze: hopper, barrel, hamwe na screw. Buri gice kigira uruhare mubikorwa no gutondeka inzira.

Hopper

Hopper ikora nk'ahantu hinjirira ibikoresho bya pulasitiki mbisi. Ifata pellet ya plastike ikayigaburira muri barriel kugirango irusheho gutunganywa. Ibyiringiro bigezweho bikunze gushiramo ibintu nka sisitemu yo kumisha ibikoresho kugirango ikureho ubuhehere muri pellet, byemeze neza neza gushonga. Mugukomeza gutanga ibikoresho bihoraho, hopper ishyigikira umusaruro udahwema kumashini ya Inkingi yo gutera inshinge.

Barrel

Barrale nicyumba cya silindrike kibamo uburyo bwa screw. Ashyushya peletike ya plastike kugeza aho ishonga ikoresheje ahantu hashyuha. Utu turere - ubusanzwe tugabanijwemo ibiryo, inyuma, hagati, imbere - byemerera kugenzura neza ubushyuhe, bukaba ari ingenzi mu kugera ku bwiza bumwe bwo gushonga. Gukwirakwiza ubushyuhe bukwiye muri barriel birinda ibibazo nkintambara, ibipimo bidahwitse, hamwe no kwangirika kwibintu. Igenzura ryitondewe ryemeza ko Imashini ya Inkingi yo guterwa imashini itanga imashini itanga umusaruro mwiza.

- Ubushyuhe bukwiye bwa zone ya barrel nibyingenzi kugirango bikore neza.

- Igenamiterere ritari ryo rishobora kuganisha ku nenge ku bicuruzwa byanyuma.

- Ibishushanyo bigezweho bitezimbere ingufu kandi bigabanya ibiciro byakazi.

Uburyo bwa tekinike

Uburyo bwa screw ni umutima wigice cyo gutera inshinge. Irazunguruka muri barrale, kuvanga no gushonga pellet ya plastike mugihe usunika ibikoresho byashongeshejwe imbere. Igishushanyo cya screw kigira uruhare runini muburyo bwo gushonga no gutera inshinge. Kurugero, uhagazeibishushanyo mboneraongera plastike mukwemeza kwogoshesha kwama no kurasa. Byongeye kandi, ibiranga nka poppet valve itanga igenzura ryukuri muguhagarika ako kanya iyo screw ihagaze.

Imashini zose zamashanyarazi Ubwoko bwa Injection Molding Machine, uburyo bwa screw butanga kugenzura ntagereranywa kumuvuduko, umuvuduko, hamwe nu mwanya. Ubu busobanuro bugabanya itandukaniro riri hagati yizunguruka, ryemeza ibipimo byuzuye byuzuye hamwe nubunini bwamasasu. Iterambere ntabwo ritezimbere ubuziranenge gusa ahubwo binongera imikorere rusange yuburyo bwo kubumba.

- Automatisation na robotics guhuza byongera umusaruro.

- Igishushanyo mbonera gikoresha ingufu zigira uruhare mu kuzigama amafaranga.

- Imikoreshereze irambye yibikoresho ihuza nibikorwa bigezweho byo gukora.

Igice cyo gutera inshinge zo mu bwoko bwa Screw Ubwoko bwa Injection Molding Machine irerekana ubufatanye bwubuhanga buhanitse no kugenzura neza. Ibigize birakorana hamwe kugirango bitange umusaruro mwiza, mwiza, kandi wizewe.

Ibice hamwe no kubumba

Ibice bifata kandi bibumbabumbwa nibintu byingenzi bigize imashini ibumba inshinge. Bemeza ko ifumbire ikomeza gufungwa neza mugihe cyo gutera inshinge kandi ikorohereza gukora ibice byuzuye, byujuje ubuziranenge. Ibi bice bigizwe nububiko, platine, hamwe na moteri, buri kimwe kigira uruhare rutandukanye muburyo bwo kubumba.

Ibishushanyo

Ifumbire ikora nk'urwobo aho plastiki yashongeshejwe ifata. Igishushanyo cyacyo kigira ingaruka zitaziguye ubuziranenge no guhuza ibicuruzwa byanyuma.Imyitozo myiza mugushushanyashimangira uburebure bwurukuta rumwe kugirango wirinde inenge nko kurigata no kurohama mugihe cyo gukonja. Inzibacyuho yoroshye hagati yubunini butandukanye, igerwaho binyuze muri chamfers cyangwa kuzuza, kurushaho kuzamura ubusugire bwimiterere.

- Ubunini bwurukuta rwirinda amakosa yo kwisiga nko gutobora no kurohama.

- Imbaraga zubaka zirashobora kunozwa nimbavu na gussets aho kongera umubyimba.

- Igishushanyo mbonera (DOE) tekinike ifasha kumenya inenge hakiri kare, kwemeza imikorere myiza no kwizerwa.

Mu mashini yerekana imashini itera inshinge, ubudodo bwuzuye bwerekana neza ko ibishushanyo mbonera no kwihanganirana bigerwaho. Ubu bushobozi butuma biba byiza kubyara ibice bigoye bifite ubuziranenge buhoraho.

Amashanyarazi

Amashanyarazi nini nini, isahani ifashe ifumbire mumwanya kandi ikwirakwiza imbaraga zo gufatana neza. Igishushanyo cyabo hamwe nuburinganire bwimiterere nibyingenzi mugukomeza guhuza no kugenzura igitutu kimwe mugihe cyo gutera inshinge. Ibyingenzi byingenzi bya tekinike bigira ingaruka kumikorere ya platine harimo ingaruka zuburemere, ubushobozi bwo kwikorera imitwaro, hamwe no gutezimbere imiterere.

| Parameter | Ingaruka ku Guhuza Ibishushanyo |

|---|---|

| Ingaruka Ibiro | Igizwe hafi 70% yuburemere bwimashini yose, bigira ingaruka kumurongo no guhuza. |

| Akamaro k'ubukungu | Gutezimbere igishushanyo kigabanya gukoresha ibikoresho fatizo, kuzamura ibiciro neza. |

| Ingaruka z'imikorere | Iremeza guhuza neza no gukwirakwiza igitutu kimwe, ingenzi kubyara umusaruro mwiza. |

| Gukoresha uburyo bwiza | Kuzamura ingano, imiterere, hamwe nogukwirakwiza ibikoresho kugirango bihuze neza. |

| Ubushobozi bwo Kwikorera Imizigo | Itezimbere kuramba kandi ishyigikira guhuza ibishushanyo munsi yibikorwa. |

Mu mashini ya Inkingi yo gutera inshinge, platine igira uruhare mubushobozi bwimashini yo gukora ibice bifite uburinganire buringaniye. Igishushanyo mbonera cyabo gikomeza kuramba no gukora neza, kabone niyo haba hari imbaraga zikomeye.

Ikinyabiziga

Ikinyabiziga gifite moteri gikoresha uburyo bwo gufatana, bigatuma ifumbire yo gufungura no gufunga neza. Ifite uruhare runini mukubungabunga umuvuduko nukuri kubikorwa byo gufatana.Imodoka igezweho, cyane cyane mumashini yose yamashanyarazi, tanga uburyo bunoze bwo kugenzura imbaraga zifatika no guhagarara. Ubu busobanuro bugabanya kwambara kumurongo kandi bigabanya ibihe byizunguruka, bizamura imikorere muri rusange.

Imashini ikoresha moteri ikoresha ingufu nayo igira uruhare mu kuzigama no kuramba. Muguhindura ikoreshwa ryingufu, bahuza nibikorwa bigezweho byo gukora bishyira imbere inshingano zidukikije. Mu mashini yo mu bwoko bwa Screw Ubwoko bwo Gutera Imashini, moteri itanga imikorere idahwitse, ishyigikira umusaruro wihuse utabangamiye ubuziranenge.

Inama:Kubungabunga buri gihe moteri irashobora kongera igihe cyayo kandi ikarinda igihe cyateganijwe gitunguranye, bigatuma umusaruro udahagarara.

Ibice bifatanye kandi bibumba byerekana ubufatanye bwubuhanga nubusobanuro bwimashini zitera inshinge. Igishushanyo mbonera n'imikorere yabo bigira uruhare runini mubushobozi bwimashini yo gukora ibice byujuje ubuziranenge neza kandi byizewe.

Sisitemu yo kugenzura ubushyuhe n'ubushyuhe

Sisitemu nziza yo gushyushya no kugenzura ubushyuhe ningirakamaro mugukomeza ubuziranenge no guhora muburyo bwo gutera inshinge. Izi sisitemu zemeza ko ibikoresho bya pulasitiki bigera aho bikwiye gushonga kandi ko ubushyuhe bwibumba buguma buhagaze neza muri buri cyiciro.

Amashanyarazi

AmashanyaraziGira uruhare runini mu gushonga pelleti yubushyuhe bwiza. Bakoresha ahantu hashyuha kugirango bagere ku bushyuhe nyabwo, bukenewe muburyo bwiza bwo gushonga. Gucunga neza ubushyuhe byongera ingufu kandi bikanonosora ubuso bwibice byabumbwe.

- Kugenzura neza ubushyuhe bwa barriel birinda kwangirika kwibintu, cyane cyane mugihe kinini cyo gutura.

- Kugumana ubushyuhe bwashushe bugera kuri 490 ° F butuma ibintu bigenda neza kandi bikagabanya inenge.

- Imihindagurikire yubushyuhe bwa barrale irashobora kugira ingaruka mbi kubicuruzwa, bigatuma gukurikiranira hafi ari ngombwa.

Igishushanyo mbonera cya barriel gikubiyemo ibintu byinshi bishyushya ingufu, kugabanya ibiciro byakazi mugihe ukomeza gukora cyane. Ibiranga bihuza nibikorwa bigezweho byo gukora bishyira imbere kuramba no gukora neza.

Ubushyuhe

Ubushyuhe bwububiko bugena ubushyuhe bwububiko, butanga ubuziranenge bwibice kandi bikagabanya ibihe byizunguruka. Ubunini bwibintu bibumba bigira uruhare runini mubipimo byo kohereza ubushyuhe. Ibice byimbitse bigumana ubushyuhe igihe kirekire, mugihe ibice byoroheje bikonje vuba. Guhindura ibishishwa bishyushya bishingiye kububyimbye bwibintu birinda ibibazo nko guhindagurika kandi bigabanya ubushyuhe bumwe.

Ubuhanga bwa Molding tekinike irusheho kunoza imikorere yubushyuhe. Ubu buryo bugabanya igihe cyo gutangira, kugabanya igipimo cyakuweho, no kuzamura gahunda ihamye. Mugukomeza ubushyuhe bwuzuye, ababikora bagera ku nyungu nini kandi nziza.

Uburyo bwo kugenzura ubushyuhe

Uwitekauburyo bwo kugenzura ubushyuheitanga ituze nukuri mugihe cyo kubumba. Ingamba zateye imbere, nkinzobere zishobora guhinduka fuzzy igenzura, ihuza igenzura rya PID gakondo hamwe na logique ya fuzzy kugirango ubushyuhe bwa barriel. Ubu buryo bugabanya kugabanuka no kunyeganyega, kunoza imikorere muri rusange.

| Ingamba zo Kugenzura | Ibisobanuro |

|---|---|

| Impuguke Guhindura Igenzura rya Fuzzy | Ihuza impuguke, fuzzy, na PID igenzura kugirango iteze imbere kandi neza. |

| Igenzura rya PID | Uburyo gakondo bukunda kurasa no kunyeganyega. |

| Icyitegererezo cyo Kugenzura | Kurikirana umuvuduko wo gutera inshinge, kunoza neza muburyo bwo kubumba. |

Imashini yiga imashini, nka algorithms yishyamba idasanzwe, nayo igira uruhare mubikorwa byingufu muguhitamo ibintu byingenzi bigira ingaruka kumikoreshereze yingufu. Ibi bishya bifasha ababikora kuringaniza imikoreshereze yingufu hamwe nubwiza bwigice, bikarushaho kuzamura irambye ryibikorwa byo gutera inshinge.

Ibice bya Hydraulic nubugenzuzi

Ibice bya hydraulic nubugenzuzi nibintu byingenzi bigize imashini ibumba inshinge. Sisitemu ikorana kugirango irebe imikorere nyayo, imikorere inoze, naubuziranenge bwibicuruzwa.

Sisitemu ya Hydraulic

Sisitemu ya hydraulic iha imbaraga urujya n'uruza rwo gutera inshinge. Itanga imbaraga zisabwa kugirango ushiremo plastike yashongeshejwe mubibumbano kandi bigumane umuvuduko wo gufatana mugihe cyo kubumba. Hydraulic pompe, valve, na silinderi bigize intandaro yiyi sisitemu, itanga imikorere igenzurwa kandi yizewe.

Sisitemu ya hydraulic igezweho ikubiyemo tekinoroji igezweho kurikuzamura imikorere. Amapompe ahindagurika yimodoka ahindura igipimo cyurugendo rushingiye kumashini ikenera, kugabanya ingufu zikoreshwa. Byongeye kandi, indangagaciro zingana zitanga kugenzura neza umuvuduko nigitemba, byemeza neza kandi neza. Ibiranga bigira uruhare mubushobozi bwimashini yo gukora ibice byujuje ubuziranenge hamwe n imyanda mike.

Inama:Kubungabunga buri gihe ibice bya hydraulic, nko kugenzura ibimeneka no kugenzura ubuziranenge bwa peteroli, birashobora kongera igihe cya sisitemu no gukumira igihe.

Akanama gashinzwe kugenzura

Igenzura rikora nkubwonko bwimashini itera inshinge. Ikurikirana kandi ikagenzura imikorere yimashini zose, ikemeza imikorere myiza. Hamwe na sensor, akanama gashinzwe gukusanya amakuru nyayo kubintu byingenzi nkubushyuhe, umuvuduko, numwanya. Urugero:

- Sensors ipima kandi itanga ibitekerezo kubushyuhe n'umuvuduko.

- Ibyuma byerekana ibyuma byerekana ibipimo bifatika ukoresheje ingirabuzimafatizo.

Imashini yiga imashini yinjijwe mumwanya wo kugenzura irusheho kongera ubushobozi bwayo. Izi moderi ziteganya ibice byubuziranenge nkibisubizo byumusaruro hamwe na modulus, gutezimbere igenamigambi ryibisubizo bihamye. Ubushakashatsi bwakozwe bwemeza ubwo buryo bwo kugereranya indangagaciro zahanuwe n’ibisubizo nyabyo, byemeza imikorere yazo mu kuzamura umusaruro.

Ibice bya hydraulic nubugenzuzi byerekana ubufatanye bwikoranabuhanga rya mashini na digitale, byemeza neza kandi byizewe mumashini ibumba inshinge.

Uburyo bwo kugaburira no gusohora

Igice cyo kugaburira

Uwitekakugaburiraitanga itangwa ryibikoresho bya pulasitiki mbisi kumashini itera inshinge. Mubisanzwe bigizwe na hopper na screw yo kugaburira. Hopper ibika pellet ya plastike ikayiyobora muri barriel, aho ibikoresho bigenda bishonga. Imbaraga rukuruzi hamwe no kunyeganyega byorohereza urujya n'uruza rwa pellet, birinda guhagarara cyangwa guhagarara mugihe cyo gukora.

Ibice bigaburira bigezweho akenshi birimo ibintu byateye imbere nka sisitemu yo kumisha ibikoresho. Izi sisitemu zikuraho ubuhehere muri pellet, nibyingenzi mukubungabunga ubwiza bwashonga no gukumira inenge mubicuruzwa byanyuma. Byongeye kandi, uburyo bwo kugaburira bwikora bwongera imbaraga muguhuza ibikoresho hamwe numuvuduko wimashini. Iyi syncronisation igabanya imyanda yibikoresho kandi ikemeza ko umusaruro udahagarara.

Igice cyo Gusohora

Uwitekaigice cyo gusohoraigira uruhare runini mugukuraho igice cyabumbwe mu cyuho kimaze gukonja. Ikoresha pine, isahani, cyangwa ibisasu byo mu kirere kugirango irekure ibicuruzwa byarangiye nta byangiritse. Icyitonderwa mugihe cyo gusohora n'imbaraga ningirakamaro kugirango ukomeze ubusugire bwigice cyabumbwe kandi wirinde inenge nko guturika cyangwa guturika.

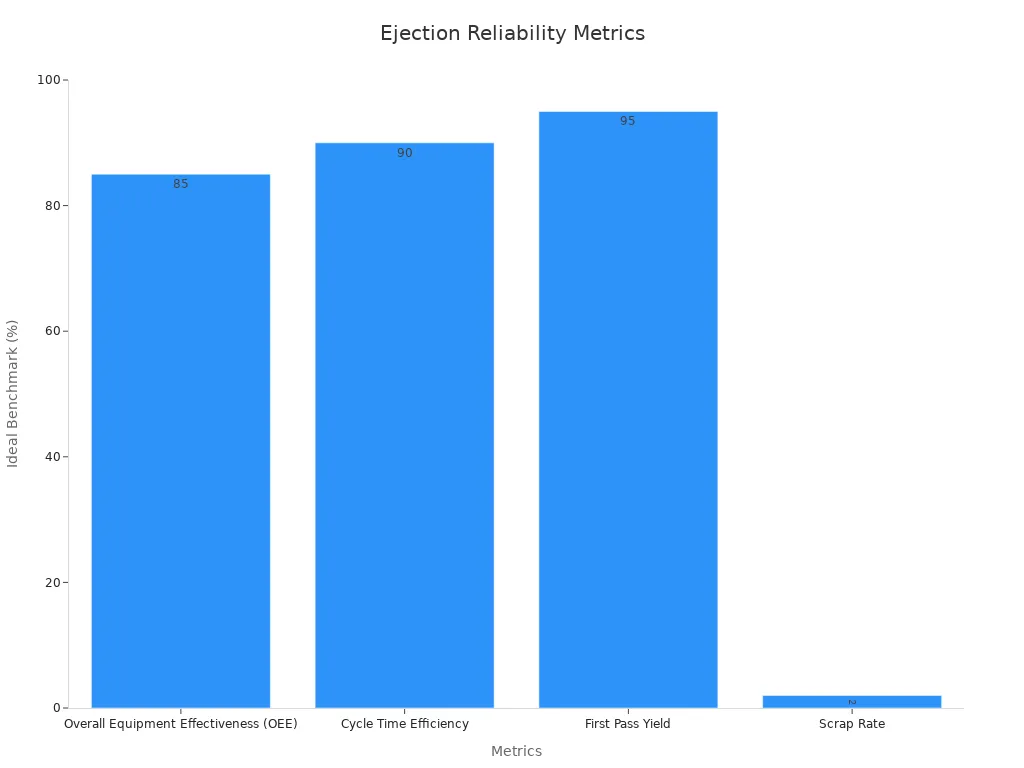

Ibice byo gusohora byizewe bigabanya cyane umusaruro wigihe cyigihe. Ibipimo nkibikoresho rusange muri rusange (OEE), Igihe Cyiza Cyiza, na Pass Yambere Yambere (FPY) byemeza imikorere yabo. Urugero:

| Ibipimo | Ibisobanuro | Ibipimo byiza |

|---|---|---|

| Muri rusange ibikoresho bikoreshwa neza (OEE) | Gupima imikorere yinganda; kubarwa uhereye kuboneka, imikorere, nubuziranenge. | ~ 85% |

| Igihe Cyiza Cyiza | Kurikirana igihe cyo kuzuza umusaruro umwe; ibihe byo hasi byongera ibicuruzwa. | 90% cyangwa irenga |

| Umusaruro Wambere (FPY) | Ijanisha ryibicuruzwa byakozwe neza igihe cyambere; indangagaciro zo hejuru zerekana inzira nziza. | > 95% |

| Igipimo cy'ibicuruzwa | Ijanisha ry'ibikoresho byajugunywe; ibiciro biri hasi byongera inyungu. | <2% |

Sisitemu yambere yo gusohora ihuza sensor kugirango ikurikirane kandi ihindure imbaraga zo gusohora mu buryo bukomeye. Ibi bishya byerekana ubuziranenge bwibice bihoraho mugihe hagabanijwe kwambara kumashini no kumashini. Kubungabunga buri gihe igice cyo gusohora byongera ubwizerwe kandi bikongerera igihe cyo gukora.

Imashini ibumba inshinge ya plastike ihuza ibice bigezweho kugirango itange imikorere idasanzwe. Buri gice kigira uruhare mu gukora neza, ubuziranenge, no kwizerwa. Kumenya sisitemu zitanga ibisubizo byiza.

| Ibipimo | Ibisobanuro |

|---|---|

| Umusaruro | Yerekana uburyo ibikoresho fatizo bihinduka mubicuruzwa byarangiye. |

| Igipimo cy'ibicuruzwa | Yerekana ijanisha ry'umusaruro utujuje ubuziranenge. |

| Imashini Yumwanya | Ingaruka kubikorwa byumusaruro nigiciro cyibikorwa, nibyingenzi kugirango byunguke. |

Gusobanukirwa ibi bipimo byerekana uruhare rwimashini mukugera kumusaruro uhoraho, wujuje ubuziranenge.

Ibibazo

1.Ni ibihe bikoresho bishobora gukoreshwa mu mashini zitera inshinge?

Imashini zibumba za plastike zitunganya thermoplastique nka ABS, polypropilene, na nylon. Bakora kandi plastiki yubuhanga nka polyakarubone na PEEK.

2. Nigute kugenzura ubushyuhe bigira ingaruka kumiterere yibicuruzwa?

Kugenzura ubushyuhe neza butuma ubuziranenge bwashonga, bugabanya inenge, kandi bugazamura ukuri. Irinda kwangirika kwibintu mugihe cyagutse cyo gutunganya.

3. Ni ubuhe buryo bwo kubungabunga butezimbere imikorere yimashini?

Gusiga amavuta buri gihe, kugenzura hydraulic sisitemu, no gusukura ibice bigaburira birinda kwambara no gutinda. Gukurikirana ibyuma byerekana imikorere ihamye kandi byongerera igihe imashini.

Igihe cyo kohereza: Gicurasi-28-2025