Imbaraga zogosha zigira uruhare runini mumikorere ya plastike twin screw extruder. Yerekeza ku mbaraga zitera ibice byibintu kunyerera, bigira ingaruka zikomeye kubintu. Kurugero, imbaraga zo gukata zongera imbaraga zo kuvanga no gukwirakwiza ubushyuhe. Muri aImpanga ya plastikeIgishushanyo mbonera cya zone ishushanya ibintu neza mugihe hagabanijwe ubushyuhe bwubushyuhe, kuko umuvuduko wa bar 40 ushobora kuzamura ubushyuhe kuri 20 ° C. Byongeye kandi, aTwin Twin Screw Extruder Screw Barrelkurushaho kunoza ibyo bikorwa muguhuza inkweto nimbaraga zinjira, mugihe iImpangaigishushanyo kigira uruhare mubikorwa rusange mubikorwa byo gukuramo.

Ibyibanze bya Plastike Twin Screw Extruder

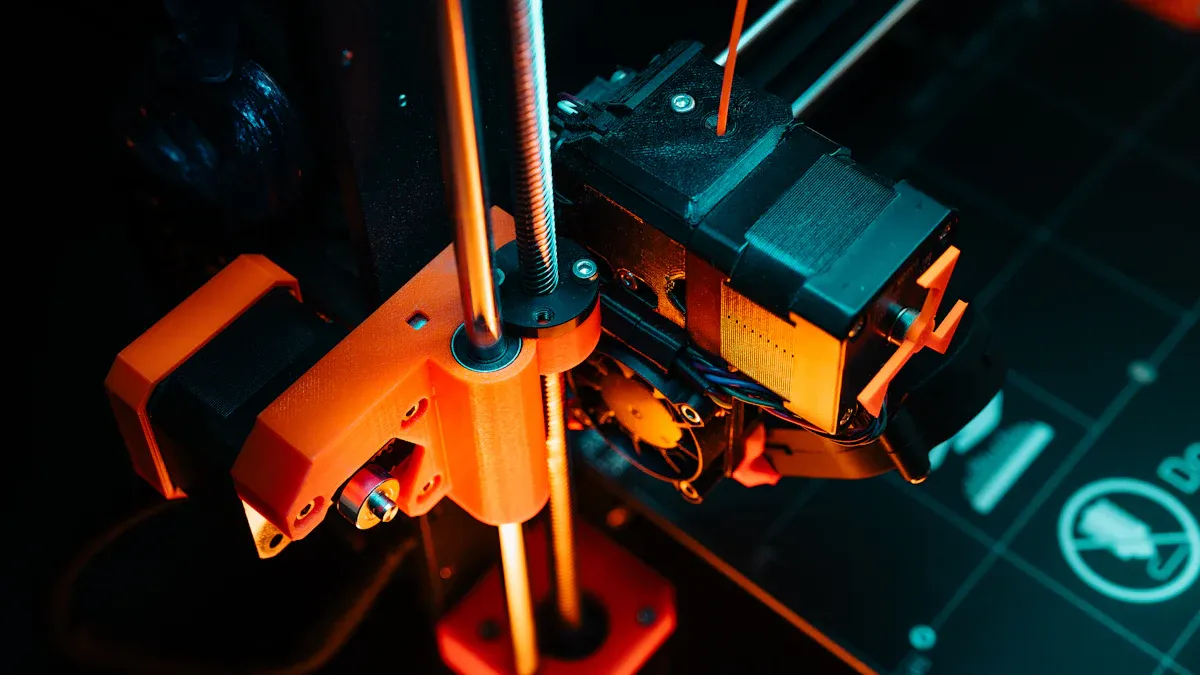

Ibice byingenzi bigize Extruder

A plastike twin screw extruderigizwe nibice byinshi bikomeye bikorana mugutunganya ibikoresho neza. Muri byo harimo:

- Hopper: Icyinjira aho ibikoresho fatizo bigaburirwa muri sisitemu.

- Barrel: Icyumba kinini aho ibikoresho bishonga kandi bivanze.

- Umuyoboro: Ashinzwe gutwara ibikoresho binyuze muri extruder.

- Sisitemu yo gushyushya: Itanga ubushyuhe bukenewe bwo gushonga ibice bya plastiki.

- Kugenzura Ubushyuhe: Iremeza uburyo buhoraho bwo gutunganya.

- Umutwe: Shiraho ibikoresho muburyo bwifuzwa nkuko bisohoka muri extruder.

Buri kintu kigira uruhare runini mukwemeza ko extruder ikora neza kandi igatanga umusaruro mwiza. Kurugero, umuvuduko wa screw yihuta ituma igenzura neza inzira yo gukuramo, mugihe impfu zisimburwa zituma habaho umusaruro wubunini butandukanye.

Uruhare rw'Imigozi na Barrale mu gisekuru cya Shear Force

Imiyoboro hamwe na barrale nibyingenzi kubyara ingufu zogosha mumashanyarazi ya plastike. Imiyoboro izunguruka muri barriel, itera guterana hamwe nigitutu gishonga kandi kivanga ibikoresho. Ibintu nkumuvuduko wa screw, bipfa diameter, nimyitwarire yibintu bigira ingaruka zikomeye kumashanyarazi. Urugero:

| Parameter | Ingaruka Kubyuka Byimbaraga |

|---|---|

| Umuvuduko | Umuvuduko mwinshi wongera ibicuruzwa no gukwirakwiza imbaraga, byongera imbaraga zo gukata. |

| Gupfa Diameter | Ibipimo binini bigabanya umuvuduko nimbaraga, bigira ingaruka kumyogosho. |

| Imyitwarire y'ibikoresho | Ibikoresho byogosha byerekana imbaraga nke ugereranije namazi ya Newtonian. |

Iyi mikoranire itanga ibikoresho neza no kuvanga kimwe.

Ibikoresho bitemba bigenda neza muri Extruder

Ibikoresho bigenda neza muri plastiki twin screw extruder igena ubwiza bwo kuvanga nibicuruzwa byanyuma. Uburyo bwiza bwo kubara, nka CFD, bwongereye gusobanukirwa izi mbaraga. Ubuhanga nkubunini-bwamazi (VOF) hamwe nuburyo bwashyizweho kurwego rukurikirana imiyoboro y'amazi mugihe cyo kuvanga, bigatuma igenzura neza inzira. Twin screw extruders ikoreshwa cyane munganda nka farumasi kubera ubushobozi bwabo bwo kuvanga. Mubihe bisanzwe (30 kg / hr, 200 rpm), igitutu mucyumba kimwe gisa na C kigera kuri MPa hafi 2.2, hamwe nigitutu cya 0.3 MPa muri zone intermeshing na 0.5 MPa mubintu byinyuma. Ibipimo byerekana imikorere ya extruder mugukoresha ibikoresho bitandukanye.

Shear Force Mechanism muri Twin Screw Extrusion

Igisekuru cya Shear Force muburyo bwo gukuramo

Imbaraga zogosha muburyo bwo gukuramo impanga zikomoka kumikoranire hagati yimigozi izunguruka na barri ihagaze. Mugihe imigozi izunguruka, itera ubushyamirane nigitutu, bigatuma ibintu bihinduka kandi bigatemba. Ihindagurika ritanga imbaraga zo gukata zigira uruhare runini mu gushonga, kuvanga, no guhuza ibikoresho. Igishushanyo mbonera cyimigozi yemeza ko uburambe bwibintu bigenda byogosha mugihe cyose.

Isesengura ryumubare ukoresheje ingano-ya-fluid (VOF) ryerekanye uburyo bwa hydrodinamike bugira uruhare muriki gikorwa. Irerekana uburyo imbaraga zo kogosha, ibipimo byijimye, hamwe n’imivurungano bigira ingaruka kuri microstructure yimvange idasobanutse mugihe cyo kuvanga. Ibyavuye mu bushakashatsi bishimangira akamaro k’imbaraga zogosha muguhitamo imyitwarire ya rheologiya nigikorwa rusange cyibikorwa byo gukuramo.

Ubushakashatsi bwubushakashatsi burashigikira ubu buryo. Kurugero, ubushakashatsi bwakozwe na polypropilene-ibumba nanocomposite bwerekanye ko impanga zo mu bwoko bwa twin screw zigera ku ntera isumba iyindi ugereranije na screw imwe. Ibi biterwa nimbaraga zo hejuru zogosha zakozwe muri sisitemu ya twin screw, izamura exfolisiyonike yibikoresho kandi igateza imbere imashini nubushyuhe.

Ibintu bigira ingaruka ku mbaraga zogosha

Ibintu byinshi bigira ingaruka ku gisekuru nubunini bwimbaraga zogosha muri plastike yimpanga ya plastike. Harimo umuvuduko wa screw, screw geometrie, hamwe nubwiza bwibintu.

- Umuvuduko: Kongera umuvuduko wa screw bizamura igipimo cyogosha, biganisha kumasoko yo hejuru. Ariko, umuvuduko ukabije urashobora gutera kwangirika kwibintu cyangwa gushyuha.

- Genda Geometrie: Igishushanyo cyimigozi, harimo ikibanza cyabo, ubujyakuzimu bwindege, hamwe nu mpande zombi, bigira ingaruka ku gikorwa cyo kogosha. Kurugero, imigozi ifite indege zimbitse zitanga imbaraga zo gukata hasi, mugihe impande zombi zuzuzanya zongera ubukana.

- Viscosity: Ibikoresho-byinshi cyane bisaba imbaraga zo gukata kugirango bigere kuvangwa no gushonga. Ibinyuranye, ibikoresho-byo hasi cyane birashobora gutemba byoroshye, bikagabanya imikorere yibikorwa byo kogosha.

Ubushakashatsi bwibarurishamibare bwasesenguye ibi bintu ku buryo burambuye. Kurugero, ubushakashatsi bwerekanye ko ibiteranyo byiyongera byiyongera kumurongo wihuta ariko bikagabanuka nigipimo cyibiryo. Uburyo bwiza bwo gutunganya neza, nkigipimo cyo kugaburira 3,6 kg / h ku muvuduko wa screw ya 95 rpm, kongera ubushyuhe mugihe ugabanya fibre. Ibyavuye mu bushakashatsi byerekana ko ari ngombwa kuringaniza ibyo bintu kugirango bigerweho neza.

Uburyo bwo kugenzura ingufu zogosha

Kugenzura imbaraga zogosha ningirakamaro mugutezimbere uburyo bwo gukuramo no kwemeza ubuziranenge bwibicuruzwa. Uburyo butandukanye burashobora gukoreshwa mugutunganya imbaraga zogosha mugace ka twin screw:

- Guhindura Umuvuduko Wihuta: Abakoresha barashobora kongera cyangwa kugabanya umuvuduko wa screw kugirango bahindure igipimo cyogosha kandi bagere kubintu bifuza.

- Guhindura Igishushanyo: Kudoda imigozi ya geometrie, nko guhindura ikibuga cyangwa ubujyakuzimu bwindege, bituma igenzura neza ibikorwa byo kogosha.

- Gukoresha Shear-Thinning Models: Izi moderi zifasha guhanura imyitwarire yibintu mubihe bitandukanye byogosha, bigafasha kugenzura neza inzira. Ariko, kwishingikiriza gusa kuri ziriya moderi birashobora gutuma umuntu adaha agaciro ibipimo byingenzi nkumuvuduko nubwiza.

- Gushyira mubikorwa Sisitemu yo Gukurikirana: Kugenzura-igihe nyacyo ibipimo nkubushyuhe, umuvuduko, na torque bitanga ubushishozi mubikorwa byo gukuramo. Aya makuru arashobora gukoreshwa muguhindura no gukomeza urwego rwiza rwiza.

Ubushakashatsi bwerekanye ko uruhare rwa screw mu guhererekanya ubushyuhe ari ingenzi mu kugenzura ingufu zogosha. Inzira yumuzunguruko ikora muri extruder, ifasha gukwirakwiza ubushyuhe buringaniye kandi ikarinda ubushyuhe bwaho. Ibi byemeza ko polymer ishonga kimwe, bikazamura imikorere rusange yimikorere.

Ingaruka zingufu zogosha kubintu bifatika

Ingaruka zo Kuvanga no Guhuza ibitsina

Imbaraga zogosha zigira uruhare runini mugushikira kuvanga hamwe no guhuza ibitsina mubikoresho bitunganywa na plastike yimpanga ya plastike. Imikoranire hagati ya screw na barrale itera guterana amagambo, byorohereza kuvanga polymers ninyongera. Iyi nzira iremeza ko ibicuruzwa byanyuma byerekana imitungo ihamye muburyo bwayo.

Ubushakashatsi bufatika bugaragaza ibintu byinshi byerekana ingaruka zogosha:

| Ibice bya Shear Force Ingaruka | Ibisobanuro |

|---|---|

| Kumena fibre | Imbaraga zogosha muri matrix yashongeshejwe ziganisha kumeneka ya fibre, bigira ingaruka kumiterere yibicuruzwa byanyuma. |

| Ubushuhe | Hafi ya 80% yubushyuhe bukenewe kugirango ushonge buterwa no guterana amagambo bitewe no gukata hagati yimigozi na barriel. |

| Kuvanga Imikorere | Igishushanyo cyo kuvanga uturere hamwe imbere- na reaction-itanga ibintu bigira ingaruka kumuvuduko wumuvuduko no kuvanga neza. |

| Ikwirakwizwa ryigihe cyo gutura | RTD igira ingaruka cyane kubiranga ibicuruzwa muguhitamo igihe cyo guhura nubushyuhe, umuvuduko, nogosha. |

Byongeye kandi, kongera umuvuduko wa rotor mugihe cya polypropilene-sisal gushonga-kuvanga ibisubizo bivamo fibre nyinshi, bikabyara uburebure bwa fibre. Iyi phenomenon, igaragara muri fibre naturel, ibaho kubera ko shear itandukanya fibre ihujwe, igabanya diameter. Ibyavuye mu bushakashatsi bishimangira akamaro ko guhuza imbaraga zo kuringaniza imvange no gukora neza.

Ingaruka kumiterere yubushyuhe no gukwirakwiza ubushyuhe

Imbaraga zogosha zigira ingaruka zikomeye kumiterere yubushyuhe no gukwirakwiza ubushyuhe mugihe cyo gukuramo. Ubuvanganzo butangwa na screw bugera kuri 80% yubushyuhe bukenewe kugirango ushongeshe ibice bya plastiki. Gukwirakwiza ubushyuhe bituma gushonga kimwe kandi bikarinda ubushyuhe bwaho, bushobora gutesha agaciro ubwiza bwibintu.

Igishushanyo cya uduce twavanze na extruder irusheho kongera ihererekanyabubasha. Imbere- na revers-itanga ibintu bitera imbaraga imbaraga zogutezimbere ubushyuhe bwumuriro. Isaranganya ryigihe cyo gutura (RTD) naryo rifite uruhare runini. Ibikoresho byerekanwe nimbaraga zogosha zihoraho zifite ubushyuhe bumwe, bikavamo ubushyuhe bwiza.

Kurugero, ibigereranyo byumubare byerekana ko imbaraga zogosha zigira ingaruka kuri microstructure ya alloys idasobanutse mugihe cyo kuvanga. Izi mbaraga zigira ingaruka ku bipimo byijimye no guhungabana, bigatuma ndetse no gukwirakwiza ubushyuhe mubintu. Ibyavuye mu bushakashatsi byerekana akamaro kogosha imbaraga mukubungabunga ubushyuhe bwumuriro mugihe cyo gukuramo.

Impinduka mubintu bya mashini nimbaraga zimbaraga

Imbaraga zogosha zigira ingaruka kumiterere yubukorikori n'imbaraga z'ibikoresho byakuwe hanze. Guhindagurika muburyo bukomeye birashobora guhindura imiterere ya molekile, biganisha kumpinduka zingufu zingutu, elastique, hamwe nigihe kirekire.

Ubushakashatsi butari buke bugaragaza izi ngaruka:

- Imbaraga zogosha zingirakamaro zingero zifatika ziyongera zidafite umurongo hamwe nibibazo bisanzwe, mugihe imbaraga zo gukata zisigaye zerekana isano rito hamwe na morphologie.

- Mugihe cyo guhangayika gisanzwe, ingero zigaragaza ubwonko bwogosha, bugabanuka kurwego rwo hejuru. Iyi myitwarire yerekana isano iri hagati yimuka isanzwe kandi igaragara.

- Ibiranga kunanirwa biratandukanye hamwe. Uturere twinshi cyane twerekana uhagaritse kandi twogosha, mugihe uturere duto duto twerekana kunanirwa gukata ku cyerekezo cyogosha.

Ibyavuye mu bushakashatsi bishimangira akamaro ko kugenzura imbaraga zogosha kugirango ugere kubintu byifuzwa. Kurugero, gukata cyane birashobora gutera fibre kumeneka, kugabanya imbaraga zumubiri. Ibinyuranye, kogosha bidahagije bishobora kuvanga kuvanga bituzuye, kubangamira ubuziranenge bwibicuruzwa.

Inyigo Yakozwe: Imyitwarire Yibintu Bitandukanye

Ubushakashatsi bwakozwe butanga ubushishozi bwukuntu imbaraga zogosha zigira ingaruka kumyitwarire yibintu. Ubushakashatsi kuri polypropilene-ibumba nanocomposite yerekana kotwin screw extruderskugera kumurongo ukabije ugereranije na sisitemu imwe ya screw. Imbaraga zo kogosha zo hejuru zongera exfolisiyoneri, zitezimbere imashini nubushyuhe.

Ubundi bushakashatsi bwakozwe kuri fibre naturel bugaragaza ko ubwoya bwakoreshejwe mugihe cyo guhuza butandukanya fibre ihujwe, igabanya diameter. Ubu buryo butezimbere uburinganire bwibintu ariko birashobora guhungabanya ubusugire bwimiterere.

Mu nganda zikoreshwa mu nganda, gukoresha ingufu zogosha byagaragaye ko ari ngombwa mu gukora ibicuruzwa byiza. Kurugero, guhindura umuvuduko wa screw na geometrie muri plastiki ya twin screw extruder itanga kuvanga kimwe nibintu bifatika. Izi nyigisho zerekana akamaro ko kudoda imbaraga zogukoresha porogaramu zihariye.

Ingamba zo Gukwirakwiza Amashanyarazi ya Plastike Twin Screw Extruder

Igishushanyo mbonera no Guhindura Iboneza

Kunoza igishushanyo mbonerani ngombwa mugutezimbere imikorere ya plastike twin screw extruder. Guhindura ibice bya geometrie, nk'ikibanza, ubujyakuzimu bw'indege, hamwe no guhuza inguni, bigira ingaruka ku buryo butaziguye kubyara no gutembera kw'ibintu. Kurugero, imigozi ifite indege yimbitse igabanya ubukana bwikariso, mugihe impande zombi zuzuzanya zongera imbaraga zo kuvanga neza.

Abakoresha akenshi bashiraho ibishushanyo mbonera kugirango bahuze ibintu byihariye. Plastike-yuzuye cyane yunguka imigozi yagizwe hamwe nubujyakuzimu bunini kugirango byorohereze urujya n'uruza. Ibinyuranye, ibikoresho-byo hasi cyane bisaba inguni zifatika kugirango zogoshe bihagije. Ibi byahinduwe bitezimbere ubutinganyi kandi bigabanya gukoresha ingufu mugihe cyo gukuramo.

Kuringaniza Shear Force nubushyuhe

Kugumana uburinganire hagati yingufu zogosha nubushyuhe nibyingenzi kugirango ugere ku bwiza buhoraho. Imbaraga zogosha cyane zirashobora gutuma umuntu ashyuha, mugihe ubwoya budahagije bushobora kuvanga kuvanga bituzuye. Gucunga igitutu muri extruder bigira uruhare runini mugucunga izo mpinduka.

Kurugero, formula yerekana isano iri hagati yumuvuduko nubushyuhe: ∆T (° C) = ∆P (akabari) ÷ 2. Gutunganya kg 500 / hr kumuvuduko wurupfu rwa 40 bar bishobora kongera ubushyuhe bwashushe hafi 20 ° C. Kwinjiza pompe ya gare bigabanya umuvuduko wogusohora, kugabanya ubushyuhe bwubushyuhe no kwambara kumashanyarazi. Gufunga-gufunga umuvuduko ukabije byongera imbaraga zo gusohora, kwemeza gukwirakwiza ubushyuhe hamwe nibintu byiza.

Ubudozi bwogosha imbaraga kubikorwa byihariye bya plastiki

Ubudozi bwogosha imbaraga kubikorwa byihariye byongera imikorere yibikoresho bya plastiki. Kurugero, kongeramo plasitike kubintu bya PLA bitezimbere guhinduka, kurwanya ingaruka, hamwe nubukanishi. Gusikana amashusho ya microscopi ya electron (SEM) yerekana ko PLA ifite plastike yerekana ihindagurika ryinshi ugereranije nibintu bitarimo amashanyarazi, byerekana imyitwarire idahwitse.

Ibizamini bya flexural byerekana ko ibice bya pulasitiki bifite agaciro gake modulus, byerekana ubwiyongere bworoshye. Byongeye kandi, kongeramo plasitike bigabanya ubushyuhe bwikirahure (Tg), byoroshye gutunganya byoroshye. Ibi byahinduwe byerekana akamaro ko gutandukanya inkweto kugirango zuzuze ibisabwa byihariye bya porogaramu zitandukanye.

Uburyo bukwiye bwo gukurikirana no gupima

Sisitemu yo gukurikirana-igihetanga ubushishozi bwingirakamaro mubikorwa byo gukuramo, bifasha abashoramari guhitamo imbaraga zogosha neza. Sensors ipima ibipimo byingenzi nkubushyuhe, umuvuduko, hamwe na torque, bitanga igenzura ryukuri kubintu bisohoka.

Ubuhanga buhanitse bwo gukurikirana, nka sisitemu ifunze-izenguruka, ikomeza igenamigambi rihoraho kandi ikumira ihindagurika rishobora guhungabanya ubuziranenge bwibicuruzwa. Izi sisitemu kandi zerekana ibintu bidasanzwe mubintu bitemba, bituma abashoramari bahita bahindura. Mugukoresha amakuru yigihe-nyacyo, abayikora bemeza ko extruder ya plastike twin ikora ikora neza, igatanga umusaruro mwiza.

Imbaraga zogosha zikomeza kuba urufatiro rwibikoresho bya pulasitiki, gukuramo ibintu bifatika nko kuvanga, ubushyuhe bwumuriro, nimbaraga za mashini. Kunoza izo mbaraga byongera ubuziranenge bwibicuruzwa no gukora neza.

Gukomeza guhanga udushya mu kugenzura imbaraga bizakingura uburyo bushya bwo gutunganya plastike. Abashakashatsi naba injeniyeri bagomba gushakisha uburyo buhanitse bwo kunonosora ibyavuye hanze.

Ibibazo

Nibihe bikorwa byibanze byimbaraga zo gukata muri twin screw?

Imbaraga zogosha zorohereza gushonga ibintu, kuvanga, no guhuza ibitsina. Iremeza ubuziranenge bwibicuruzwa muguhindura ubushyuhe nubukanishi mugihe cyo gukuramo.

Nigute abashoramari bashobora kugenzura imbaraga zogosha mumashanyarazi?

Abakoresha bahindura umuvuduko wa screw, bahindure imigozi ya geometrie, kandi bakurikirane ibipimo nyabyo nkumuvuduko na torque kugirango bagenzure imbaraga zogosha neza.

Kuki kuringaniza imbaraga zogosha nubushyuhe ari ngombwa?

Kuringaniza imbaraga zogosha nubushyuheIrinda kwangirika kwibintu, yemeza kuvanga kimwe, kandi ikomeza uburyo bwiza bwo gusohora ibintu byiza cyane.

Igihe cyo kohereza: Jun-11-2025