Sisitemu imwe ya barrele sisitemu ntabwo ikubiyemo guhuza-gutandukanya cyangwa guhinduranya-gutandukanya iboneka mu bishushanyo mbonera. Muri 2025, ingunguru imwe ya screw iracyayobora isoko ryo gusohora. Imbonerahamwe ikurikira irerekana ko bakomeje kwiganza:

| Umwaka | Umugabane umwe wa Barrel Isoko Kugabana (%) | Inyandiko |

|---|---|---|

| 2023 | 60 | Umugabane munini wisoko muburyo bwa extruder |

| 2025 | ~ 60 cyangwa hejuru gato | Bigereranijwe hashingiwe ku iterambere rihamye |

Ababikora bahitamo hagati yamahitamo nkaUmuyoboro wa PVC umwe, umugozi umwe wumugozi wo guhuha, naingunguru imwe ya plastikeusuzumye igishushanyo mbonera, ibikoresho bya barriel, nibisabwa umurenge.

Umuyoboro umwe wuzuye: Ibyingenzi byingenzi

Umuyoboro wa PVC Umuyoboro umwe

Umuyoboro wa PVC umuyoboro umwe ufite uruhare runini mugukuramo imiyoboro yo kubaka, kuvoma, no gukoresha amashanyarazi. Abakora ibishushanyo mbonera hamwe na aimiterere yoroshye, bigabanya kunanirwa kwa mashini kandi bigatuma kubungabunga bitaziguye. Gukoresha imbaraga-zikomeye zivanze nicyuma hamwekuvura nitridingbyongera ubukana no kwambara birwanya. Igishushanyo cyerekana gushonga, kuvanga, no gutanga ibice bya PVC. Imbonerahamwe ikurikira irerekana ibintu by'ingenzi:

| Ikiranga | Umuyoboro wa PVC Umuyoboro umwe |

|---|---|

| Igishushanyo | Imiterere yoroshye, yizewe |

| Kubungabunga | Ubuhanga bworoshye, buke tekinike irakenewe |

| Ikiguzi cyo gukora | Imikorere yo hasi, ikora neza |

| Kugenzura Ubushyuhe | Kuborohereza kuyobora |

| Kuramba | Imbaraga zikomeye zivanze nicyuma, nitride yo kwihanganira kwambara |

| Gusaba | Nibyiza kubisanzwe bya PVC |

Izi barrale ziganje ku bicuruzwa bito n'ibiciriritse bingana na PVC kubera kwizerwa no gukoresha neza.

Umuyoboro umwe umwe wo guhuha

Ibikoresho bya screw imwe yo kuvuza ibishushanyo bifasha kubyara amacupa, kontineri, nibindi bicuruzwa bidafite akamaro. Ba injeniyeri bafite ibikoreshoimigozi yo kugaburiranindege zimbitse kugirango zongere resin gushonga no kuvanga. Inzitizi yo kuvanga igice hafi yimpera ya screw itezimbere kuvanga polymer kandi ikemeza gushonga. Igipimo kinini cyo guhunika gifasha kugera ku gushonga kwa bahuje ibitsina, ni ingenzi cyane ku gutuza kwa bubble hamwe nubwiza bwa firime. Ibishushanyo mbonera bishobora kuba birimo sensor zo kugenzura umuvuduko wubushyuhe nubushyuhe, kugenzura neza inzira. Gukoresha ibyuma bivangwa nubushyuhe bitanga ibyuma biramba kandi birwanya kwambara.

- Amashanyarazi agaburira neza atezimbere gushonga no gutanga.

- Sisitemu yo gukonjesha ikomatanya igenga ubushyuhe mugihe cyo gukuramo.

- Ibyuma bifata ibyuma bifasha kugenzura igihe nyacyo.

PE Umuyoboro wa Extruder Umuyoboro umwe

PE pipe extruder imwe ya barrele yakozwe muburyo budasanzwe bwa polyethylene. Izi barrale zituma gushonga neza, kuvanga, no gutanga ibikoresho bya PE. Igishushanyo gishyigikira ibicuruzwa byinshi kandi bihoraho byujuje ubuziranenge, byujuje ibyifuzo byinganda za PE inganda. Ababikora bakoresha ibikoresho nibishushanyo bitandukanye, nk'ibyuma bivangwa n'ibyuma na nitride, kugirango bihuze polymer n'ibikenewe. Igice cyo gusaba kirimo inganda nkimodoka, ibikoresho byo munzu, hamwe na plastiki rusange, byerekana byinshi muribi.

- Amahitamo mato, aringaniye, na nini ya diameterbikwiranye n'umunzani utandukanye.

- Gukwirakwiza ibikoresho byinshi byo gutunganya inganda nibisohoka bihoraho.

Imikorere nubushobozi muri sisitemu imwe ya Barrel Sisitemu

Kuvanga nubushobozi bwa Homogenisation

Kuvanga no guhuza ibitsina bigira uruhare runini mugikorwa cyo gukuramo. Sisitemu imwe ya barrele yimura ibikoresho bibisi binyuze mu kugaburira, gushonga, no gupima zone. Imashini izunguruka, ifatanije no gushyushya ingunguru, ishonga ibikoresho ikabisunika imbere. Iyi nzira irahagarika kandi ikavanga polymer yashongeshejwe, ikemeza ko igabanywa rimwe mbere yuko isohoka mu rupfu.

Ba injeniyeri bakunze kongeramo ibikoresho byo kunoza imikorere. Kuvangavanga bitandukanya, nkubwoko bwa Egan na Maddock, bisenya ibice kandi bizamura ubwiza bwo gushonga ukoresheje kogosha. Gukwirakwiza kuvanga, nka Saxton cyangwa pin ivanga, kugabana no kugabura gushonga, bifasha kugera kumabara no gukwirakwiza. Inzitizi ya bariyeri itandukanya ibyiciro bikomeye kandi bishongeshejwe, byemerera gushonga byuzuye mbere yo kuvanga. Guhitamo ibishushanyo biterwa nibikoresho hamwe nubwiza bwibicuruzwa byifuzwa.

Inama:Guhitamo kuvanga neza hamwe na geometrie irashobora kunoza cyane homogenisation, cyane cyane kubikoresho bifite amabara cyangwa inyongeramusaruro.

Arikoinzira imwemuri barrele imwe ya screw irashobora kugabanya kuvanga. Umuvuduko wa polymer uratandukanye kumuyoboro, ushobora gutera ibicuruzwa bituzuye. Kugira ngo iki kibazo gikemuke, abajenjeri bakoresha izindi ndege no kuvanga ibice, nubwo bishobora kongera imbaraga zo guhangana nubushyuhe. Igishushanyo mbonera cya screw gifasha gutsinda izo mbogamizi, gutanga umusaruro mwiza, uhoraho.

Ibicuruzwa byinjira nibisohoka

Ibicuruzwa byinjira bipima ibintu byinshi extruder itunganya mugihe. Muri 2025, ingunguru imwe isanzwe ifite uburebure bwa mm 100 igera kuri kg 150 / hr. Igishushanyo mbonera cyiza gishobora kuzamura iki gipimo cya 18% kugeza kuri 36%. Imbonerahamwe ikurikira irerekana muri make urufunguzo rwinjiza:

| Parameter | Ibisobanuro / Indangagaciro |

|---|---|

| Kuramo Diameter | Mm 100 |

| Ibisanzwe Byinjira | 150 kg / hr |

| Ibipimo-Umuyoboro Wimbitse | Mm 4 kugeza kuri mm 8 |

| Igipimo Kwiyongera Kuburyo bwiza | 18% kugeza kuri 36% |

| Ubushyuhe ntarengwa | ~ 230 ° C. |

| Kugabanya Ibintu | Ubukonje, ubushyuhe bukabije |

Ubujyakuzimu bwimbitse muri screw bugabanya igipimo cyogosha nubushyuhe bwo gusohora, butuma byinjira cyane. Nyamara, kumanuka ukonje hamwe nubushyuhe bukabije akenshi bisohora umusaruro mwinshi. Kuringaniza geometrie, nk'ubugari n'ubugari bwa groove, nabyo bigira ingaruka ku gipimo cyo gukuramo no ku bwiza bwa plastike.

Gukoresha Ingufu no Guhagarara neza

Imashini imwe ya screw isohora imbaraga zayo mubikorwa bitaziguye. Igishushanyo cyabo cyoroshye hamwe no guhererekanya ingufu za mashini zitanga imbaraga zo hasi ugereranije na sisitemu igoye. Kubikoresho bimwe, bakoresha imbaraga nke kandi bagakoresha amafaranga make.

Ibintu byinshi bigira ingaruka kumikoreshereze yingufu:

- Imikorere ya moteri hamwe nigishushanyo cya screw bigira ingaruka kumikoreshereze yingufu.

- Sisitemu yo gushyushya no gukonjesha igira uruhare mukubungabunga ubushyuhe bwiza.

- Ibipimo bitunganijwe, nkumuvuduko wa screw nubushyuhe bwa barrale, bigira ingaruka nziza muri rusange.

Inzira ihamyeiremeza ubuziranenge bwibicuruzwa mugihe gikomeza. Ikigereranyo cy'uburebure-kuri-diameter, igipimo cyo guhunika, hamwe na screw umwirondoro byose bigira ingaruka ku gushonga no kuvanga.Guhitamo ibikoreshokuri screw na barrale bigira ingaruka kumara no guhuza na plastiki zitandukanye. Abakoresha bakurikirana ubushyuhe nigitutu bakoresheje sensor kugirango bamenye kandi bagenzure ihindagurika. Sisitemu igezweho yo kugenzura, nka fuzzy logic controllers, ifasha kubungabunga ibihe bihamye no kuzamura ubwiza bwashonga.

Icyitonderwa:Imiterere ihamye irinda itandukaniro ryimiterere yibicuruzwa no kugabanya imyanda, bigatuma kugenzura no kugenzura ari ngombwa kugirango umusaruro wizewe.

Porogaramu Ikwiranye nigishushanyo kimwe cya Barrel Igishushanyo

Guhuza Ibikoresho no gutunganya ibikenewe

Guhuza ibikoresho bihagaze nkikintu cyibanze muguhitamo ingunguru imwe ya screw yo gukuramo. Ababikora bahitamo ibikoresho bya barriel hamwe nubuvuzi bushingiye ku bwoko bwa plastiki hamwe n’ibidukikije bitunganyirizwa. Ibikoresho bikurikira bikoreshwa cyane:

- 38CrMoAIA na SKD61 zitanga kwambara no kurwanya ruswa kuri plastiki rusange.

- Bimetallic alloystanga igihe kirekire, cyane cyane kubintu bya plastiki byangiza cyangwa byongeye gukoreshwa.

- Ibishushanyo byabugenewe hamwe na barrale bihuye nibisabwa mumashini nibikoresho bitandukanye.

Ibi bikoresho bikemura ibibazo byinshi byo gutunganya, nko kurwanya kwambara, kurwanya ruswa, no gukomeza umusaruro mwinshi. Ibigega byambara-birwanya cyane biba ngombwa mugihe cyo gutunganya plastiki zuzuye cyangwa zongeye gukoreshwa. Amahitamo arwanya ruswa arinda inyongeramusaruro cyangwa polymers. Imbonerahamwe ikurikira irerekana muri make uburyo ibikoresho bitandukanye bya barrale byujuje ibyifuzo bitandukanye byo gutunganya:

| Ubwoko bwibikoresho | Umuti / Gupfuka | Gutunganya ibikenewe | Plastike ihuje |

|---|---|---|---|

| SCM-4 Ikomeye-Ikomeye ya Alloy Steel | Kuzimya-Umuvuduko mwinshi / Chrome ikomeye | Kwambara birwanya, kwangirika kwangirika, kwihanganira ubwoya n'ubushyuhe | PE, PP, PVC, ABS, nibindi |

| SACM-1 Amashanyarazi | Umuti wa Nitriding | Kunoza kwambara no kurwanya ruswa | PE, PP, PVC, ABS, nibindi |

| SCM-4 Amavuta ya Bimetallic | Ubuso bukomeye (0.8-1.2mm) | Kwiyongera kwambara no kurwanya ruswa | Plastike zitandukanye zirimo plastiki zongeye gukoreshwa kandi zuzuye |

Ba injeniyeri batekereza kandi kwagura ubushyuhe bwibikoresho birwanya ruswa. Bahuza neza imigozi na barrale kugirango birinde guhuza cyangwa kwangirika mugihe cyo gukora. Kwambara neza, nka Colmonoy cyangwa tungsten alloys, birinda kwambara nabi kandi byongerera ubuzima serivisi. Ihitamo ryemeza ko ingunguru imwe ya screw ikomeza gukora neza murwego runini rwa plastiki nuburyo bwo gutunganya.

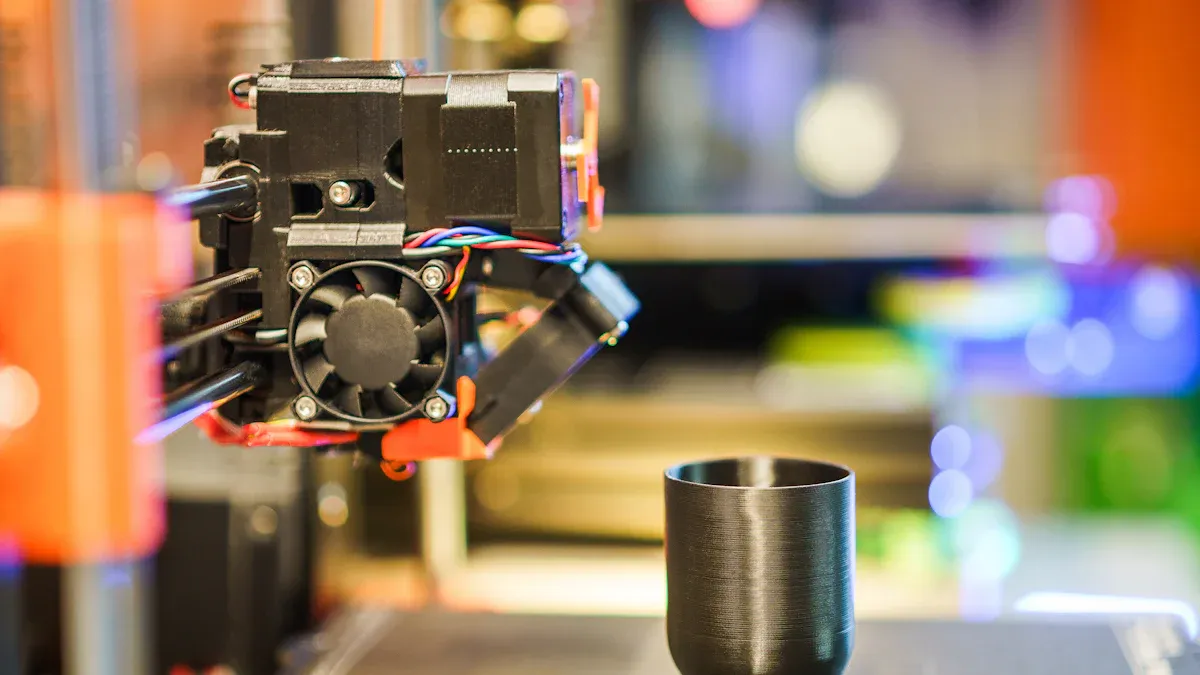

Ubwiza bwibicuruzwa no guhuzagurika

Igishushanyo mbonera cya screw imwe igira ingaruka ku buryo butaziguye ubuziranenge no guhuza ibicuruzwa biva hanze. Ikibumbano cyateguwe neza cyerekana gushonga neza, kuvanga neza, no gutanga neza kwa polymer. Iyi nzira igabanya inenge kandi ikomeza uburinganire mubicuruzwa byanyuma. Ibintu by'ingenzi bishushanya birimo:

- Ikigereranyo cy'uburebure-kuri-diametre (L / D) igenzura igihe cyo gutura no gucunga ubushyuhe.

- Ikigereranyo cyo kwikuramo na screw geometrie igena kuvanga ubukana no gushonga ubutinganyi.

- Barrel metallurgie, nka bimetallic cyangwa nitride hejuru, byongera imbaraga zo kwambara kandi bigahindura ubwiza bwumusaruro.

Gushonga neza no kuvanga birinda guhuzagurika, nkamabara akurikirana cyangwa amakosa yibipimo. Geometrie ya geometrie ifasha kugenzura ubushyuhe, kwirinda kwangirika cyangwa gushonga cyane. Umuvuduko ukwiye no kugenzura ibintu bikomeza ibintu bigenda neza, nibyingenzi muburyo bumwe nibicuruzwa. Umwirondoro wihariye, nka barrière cyangwa kuvanga ibintu, bitezimbere gushonga no gutandukanya amabara. Kubungabunga buri gihe no guhuza screw na barrale bifasha kugumya ibicuruzwa byiza mugihe runaka.

Impanuro: Guhuza ibishushanyo mbonera byubwoko bwa plastike byerekana neza ibicuruzwa byiza kandi bigabanya ibyago byinenge.

Inganda-Ibisabwa byihariye

Inganda zinyuranye zisaba ibintu byihariye mubikoresho byabo byo gukuramo. Akabari kamwe kamwe kagomba kuzuza ibyo bisabwa kugirango habeho umusaruro wizewe kandi neza. Imbonerahamwe ikurikira irerekana ibyangombwa byingenzi bikenewe mubice byingenzi bikoreshwa:

| Inganda / Gusaba | Ibisabwa by'ingenzi n'ibitekerezo |

|---|---|

| Gukuramo plastike | Huza screw barrel igishushanyo cyubwoko bwibintu (isugi, yongeye gukoreshwa, yuzuye, ivanze na polymers); Ikigereranyo cya L / D mubisanzwe 24: 1 kugeza 36: 1; Ikigereranyo cyo kwikuramo no kuvanga uturere bigenewe gutunganywa; Ubuvuzi bwo hejuru nka nitriding cyangwa bimetallic coatings kugirango wirinde kwambara; Porogaramu-yambaye cyane isaba bimetallic barrel kugirango irambe |

| Gukuramo ibiryo | Icyuho gito cya screw-barrel kugirango gikomeze kugira isuku no kwirinda kwanduza; Icyuho cyo hasi cyibicuruzwa byangiza ubushyuhe |

| Rubber na Chemical Extrusion | Gushimangira, kwambara-kutambara kugirango ukoreshe reberi yuzuye; Rimwe na rimwe, icyuho kinini kugirango ugabanye imbaraga zo gukata |

Gukuramo plastike akenshi bisaba kwihanganira screw-barrel kwihanganira hamwe no gutwikira ibintu byihariye kugirango bikore polymers zitandukanye, harimo izuzuza cyangwa ibiyikubiyemo. Gukuramo ibiryo bishyira hejuru yisuku, bisaba icyuho gito nigishushanyo gito cyo kurinda ibicuruzwa byoroshye. Gukuramo reberi na chimique byungukirwa no gutwikirwa imbaraga, hamwe na hamwe, icyuho kinini cyo gucunga ibikoresho byangiza no kugabanya kwambara.

Guhuza neza, kubungabunga, no kugenzura ubushyuhe bikomeza kugira ingaruka ku guhitamo ingunguru mu nganda zose. Gushonga neza, kuvanga, no gutanga bikomeza kuba ingenzi mugukomeza ubuziranenge bwibicuruzwa n'umurongo uhamye.

Ibiciro no Kubungabunga Ibitekerezo bya Barrique imwe

Ishoramari ryambere nibikoresho Kuramba

Ishoramari ryambere rya sisitemu imwe ya barriel muri 2025 iracyagerwaho kubakora benshi. Ibiciro mubisanzwe biva$ 10,000 kugeza 50.000, ikaba iri munsi yikiguzi cya sisitemu ya twin screw. Imbonerahamwe ikurikira irerekana ibintu byingenzi bigira ingaruka kuri ibi biciro:

| Ikintu | Ingaruka ku Biciro |

|---|---|

| Ubwiza bw'ibikoresho | Urwego rwo hejuru = igiciro kiri hejuru |

| Urwego rwo kwikora | Automatic nyinshi = igiciro kinini |

| Guhitamo | Ibishushanyo bidasanzwe = igiciro kinini |

| Abatanga Icyubahiro | Birazwi = igiciro kiri hejuru |

Ibikoresho byo kugaburira umugozi umwe ukoresha tekinoroji nubushakashatsi byoroshye, bigatuma ishoramari ryambere no kubungabunga bikenera bike. Ubu bworoherane kandi bufasha kugabanya ibyago byo gutsindwa kwa mashini. Kuramba kw'ibikoresho biterwa no guhitamo ibikoresho, gushushanya imigozi, no kubungabunga buri gihe. Iterambere ryimbere hamwe na bimetallic barrele irashobora kongera igihe cya serivisi, cyane cyane mugutunganya ibikoresho byangiza.

Amafaranga yo gukoresha no gukoresha ingufu

Igiciro cyo gukoresha kuri sisitemu imwe ya barriel guma guma guma kubera gukoresha ingufu zihamye. Gukoresha ingufu nyinshi biva mu gushyushya ingunguru no gukoresha moteri ya screw, ubusanzwe bisaba hagati ya 3 na 50. Moteri ya screw ubwayo ikoresha kilo 7 kugeza kuri 15. Kuberako ingufu zikenewe zikomeza kuba nziza, abayikora barashobora gukoresha bije byoroshye kandi bagakomeza kugenzura ibicuruzwa. Uwitekaimirimo ya mashini ya screw nayo itanga ubushyuhe bwimbere, bigabanya gukenera ubushyuhe bwiyongereye kandi bitezimbere ingufu. Gukoresha tekinoroji yo kuzigama ingufu nka drives yumurongo uhinduka hamwe na sisitemu yo kugenzura birashobora gukomeza kugabanya ibiciro.

Impanuro: Gukoresha ingufu zihamye mugusohora biganisha ku gusiba bike no gukora neza ibikoresho ugereranije nibindi bikorwa.

Kubungabunga no Kwambara Ibintu

Gufata neza ingunguru imwe yibanda ku gucunga imyenda no gukomeza sisitemu ikora neza. Inzitizi zisanzwe zirimo ubuziranenge bwo gushonga budahuye, kwambara byihuse bivuye mubikoresho byangiza, hamwe no kutinjira neza. Kwambara ibintu nkibintu byuzuza ibintu, inyongeramusaruro zangiza, hamwe nubushyuhe bwo hejuru birashobora kwihutisha gukenera gusanwa. Ahantu hambaraye cyane, nko kugaburira no gusohora, bisaba kugenzurwa buri gihe. Gukoresha ibikoresho bigezweho hamwe no gutwikira bifasha kongera ubuzima bwa serivisi no kugabanya inshuro zo kubungabunga. Gahunda yo kubungabunga ibidukikije, gusukura buri gihe, no gukurikirana imyambarire yambara bituma abayikora bategura gusana no kwirinda igihe cyo gutungurana.

Ibizaza hamwe nudushya muri tekinoroji imwe ya tekinoroji

Iterambere ry'ikoranabuhanga muri 2025

Ababikora bakomeje kumenyekanisha tekinolojiya mishya itezimbere imikorere nimikorere ya sisitemu yo gukuramo. Udushya twinshi tugaragara muri 2025:

- Kunoza ibintu neza bigabanya guhagarika no gutaha, byongera igihe cyo gukora.

- Gukwirakwiza ubushyuhe bwiza bikomeza ubushyuhe bwiza bwo gutunganya, kuzamura ibintu bifatika hamwe nibicuruzwa bihoraho.

- Kwiyongera kuramba kubikoresho byujuje ubuziranenge biganisha ku gusana gake no gusimburwa, kuzigama igihe nigiciro.

- Igenamiterere ryihariye ryemerera guhuza ibikenewe byumusaruro ukenewe, kurushaho kuzamura imikorere.

Igishushanyo cya Helibar mubisekuru bizakurikiraho bitanga ibicuruzwa byinshi kandi byiza byashonga-byiyongera. Igishushanyo kandi kigabanya ubushyuhe bwo gushonga kandi bitezimbere gushonga ubutinganyi. Kugabanya kwambara ingunguru nigihe gito cyo gutura bifasha kugumana ubuziranenge bwibicuruzwa. Inganda nyinshi ubu zikoresha uburyo bwo guhanura hamwe na sisitemu yo kugenzura igezweho mu rwego rwo gukora ubwenge. Izi sisitemu zikurikirana ibikoresho byubuzima hamwe nibipimo bitunganijwe mugihe nyacyo, bifasha gukumira igihe cyo gutungurana gitunguranye kandi kigakora imikorere ihamye.

Ibisabwa ku isoko no Kuramba

Ibigenda ku isoko muri 2025 byerekana impinduka zihuse mu nganda za plastiki no kurushaho kumenyekanisha ibidukikije. Impamvu nyinshi zituma hakenerwa ibikoresho byo gukuramo ibikoresho:

- Inganda za plastiki zikura vuba, cyane cyane muri Aziya-Pasifika, kubera imijyi n’ibikenerwa n’abaguzi.

- Ibikoresho byoroheje bibona ikoreshwa ryinshi mumashanyarazi no mu kirere.

- Udushya mu ikoranabuhanga, nka barrière ya barrière hamwe na CAD / CAM yihariye, bitezimbere imikorere no kugabanya ikoreshwa ryingufu.

- Amabwiriza akomeye y’ibidukikije asunika abayakora gukoresha imashini zikoresha ingufu kandi zigabanya imyanda.

- Inganda zipakira ziraguka, zibanda kubintu byoroshye, biodegradable, nibindi bisubirwamo.

- Inganda 4.0 hamwe nubukorikori bwubwenge butuma ikurikiranwa ryigihe kandi rikora neza.

- Kwishyira hamwe no kugura bifasha ibigo kuzamura ubushobozi bwikoranabuhanga.

Iterambere rirambye rigira iterambere ryikoranabuhanga rya extrusion.Ababikora bafata ibikoresho bisubirwamo kandi bikagabanya imyanda yo gutunganya. Benshi bakoresha ibishishwa bitunganijwe hamwe na sisitemu yo gukora isuku kugirango bashyigikire intego zubukungu. Amasoko y'ingufu zishobora kuvugururwa nibikoresho bikoresha ingufu bifasha kugabanya ibyuka bihumanya. Iterambere ryambere hamwe nubuhanga busobanutse neza ibikoresho byo hasi hamwe no gukoresha ingufu, bigabanya ibidukikije. Iyi myitozo ifasha ibigo kubahiriza amahame akomeye y’ibidukikije no kuzamura izina ryabo ku isoko.

Amabwiriza y’ibidukikije mu turere nk’Ubufaransa n’Umuryango w’ubumwe bw’ibihugu by’Uburayi arasaba ko hajyaho imyuka ihumanya ikirere ndetse n’ibicuruzwa bitunganywa neza. Ababikora bagomba guhanga udushya kugirango bakurikize aya mategeko mugihe bakomeza gukora neza. Uyu muvuduko wamabwiriza aganisha kubisubizo birambye hamwe nishoramari rihoraho mubushakashatsi niterambere.

Guhuriza hamwe hamwe no guhinduranya impaka ntabwo bikoreshwa kuri sisitemu. Ababikora babakunda muri 2025 kubikorwa byabo, kwiringirwa, no guhuza n'imiterere. Mugihe uhisemo, bagomba guhuza igishushanyo mbonera gikenewe kubintu, tekerezakwambara, kandi ushakishe ibintu bishyigikira igenzura rya digitale n'umusaruro urambye.

Ibibazo

Ni izihe nyungu nyamukuru za barrile imwe ya screw muri extrusion?

Ingunguru imwetanga imikorere yizewe, kubungabunga byoroshye, no gukora neza. Bihuye nibisabwa bisanzwe byo gukuramo muri 2025.

Ni kangahe ababikora bagomba kugenzura ingunguru imwe?

Ababikora bagomba kugenzura ingunguru imwe imwe buri mezi atatu kugeza kuri atandatu. Kugenzura buri gihe bifasha kwirinda kwambara no kugumana ubuziranenge bwibicuruzwa.

Ese inzira imwe ya barriel ishobora gutunganya plastiki?

Yego,ingunguru imweirashobora gutunganya plastiki yongeye gukoreshwa. Gukoresha ingunguru ya bimetallic cyangwa impuzu zidasanzwe zitezimbere kwambara no kwagura ibikoresho ubuzima.

Igihe cyo kohereza: Nyakanga-10-2025