PE ntoya ya granulators ifasha abayikora kugabanya gukoresha ingufu hamwe nubuhanga bushya. Moderi iheruka kwerekana ibisubizo bitangaje:

| Ibipimo | 2025 Kugabanuka nu myaka yashize |

|---|---|

| Gukoresha Ingufu (kW-h / tonne) | 40% munsi |

| Ibyuka bihumanya ikirere | 33% munsi |

| Ikoreshwa rya peteroli | 45% munsi |

Bakoreshamoteri ikora neza, kugarura ubushyuhe, hamwe na sisitemu ikonje. AnIbidukikije Mini-Pelletizer ImashininaImashini itagira amaziirashoboraPvc Kurekuraneza.

Ingufu-Zizigama Ibiranga PE Ntoya Ibidukikije

Sisitemu Yimikorere Yimikorere

PE ntoya ya granulators muri 2025 ikoresha tekinoroji ya moteri igezweho kugirango ibike ingufu no kuzamura imikorere. Izi mashini zishingiye kubikoresho byamashanyarazi bifite ingufu za moteri kuva kuri 22 kW kugeza 110 kW, bitewe nubunini bwikitegererezo. Moteri ikorana nubushobozi kuva 200 kugeza 1200 kg / h, bigatuma ikora neza kubikorwa bito n'ibiciriritse. Imbonerahamwe ikurikira irerekana bimwe byingenzi bya tekiniki:

| Ibisobanuro | Ibisobanuro |

|---|---|

| Imashanyarazi | 22 kW kugeza 110 kW |

| Ubwoko bwa Drive | Ibikoresho byo gutwara amashanyarazi |

| Imbaraga zo gutwara ibinyabiziga | 1.1 kW |

| Urwego rwubushobozi | 200-1200 kg / h |

| Gusaba | PE hamwe na granulation ya plastike |

Moteri ikora neza cyane ikoresha servo drives hamwe nubugenzuzi bwubwenge. Bafasha abakoresha kuzigama ingufu zingana na 40% ugereranije na moteri ishaje. Kugenzura-igihe nyacyo no kwikora bituma sisitemu ikora neza, kugabanya igihe cyo kugabanya no kugabanya ibiciro byamashanyarazi.

Gukoresha icyuma cyiza no kohereza

Sisitemu yo gukwirakwiza no gukwirakwiza muri PE ntoya ya granulators ifite uruhare runini mu kuzigama ingufu. Ababikora bakoresha ibyuma byabugenewe bikozwe muri premium alloys nka tungsten karbide cyangwa ibyuma byihuta. Ibi bikoresho bimara igihe kirekire kandi bikata neza. Hano hari inzira zimwe zahinduwe neza zifasha:

- Inguni zifatika zigabanya umutwaro wa moteri no gukoresha ingufu.

- Kwambara neza, nka nitride ya titanium, guterana hasi kugera kuri 40%.

- Isuku ya ultrasonic isanzwe ituma ibyuma bikarishye kandi bikarinda kwiyubaka.

- Flat blade ikora neza kuri plastiki yoroshye, kugabanya kurwanya no kuzigama ingufu.

- Ibikoresho bikomeye-byongera ubushobozi bwumusaruro kugeza 30%.

Uruganda rwo gutunganya ibicuruzwa mu Budage rwabonye 22% mu gusimbuka neza no kugabanuka kwa 14% gukoresha ingufu kuri toni nyuma yo guhindura ibikoresho byiza. Iyo ibyuma bigumye bikarishye kandi bisukuye, imashini yose ikora neza kandi ikoresha imbaraga nke.

Ubwikorezi bwubwenge no kugenzura inzira

Ubwikorezi bwubwenge butuma PE ntoya granulators yibidukikije ndetse ikora neza. Izi mashini zikoresha sisitemu yo kugenzura PLC hamwe na ecran ya ecran kugirango ikore byoroshye. Ibiranga automatike birimo:

- Kugaburira ibinyabiziga kugenzura ibintu bigenda neza.

- Sisitemu ebyiri zungurura sisitemu zemerera abakoresha guhindura ecran badahagarara.

- Sisitemu yo gusubiza inyuma ya sisitemu yo gusohora imyanda mu buryo bwikora.

- Guhindura-auto-pelletizing icyuma umuvuduko nigitutu cya pellet imwe.

- Gukemura ibibazo kumurongo hamwe nibisobanuro byiza binyuze mugucunga ibicu.

Impanuro: Gukoresha ubwenge ntibizigama ingufu gusa ahubwo binagabanya gukenera imirimo y'amaboko. Abakoresha barashobora kwibanda kubindi bikorwa mugihe imashini ikora ibintu bisanzwe.

Ibishushanyo mbonera bihuza ibice, imashini, hamwe na extruders muri sisitemu imwe. Iyi mikorere ituma inzira ikora nta kiruhuko kirekire, bivuze ko imbaraga zidasesaguwe kandi zisohoka cyane.

Kwangiza imyanda no kuyikoresha

PE ntoya ya granulators ntabwo ireka ubushyuhe bwagaciro bugahinduka ubusa. Mugihe gikora, izo mashini zitanga ubushyuhe. Aho kuyitakaza, sisitemu ifata kandi igakoresha ubu bushyuhe kubindi bikorwa byakozwe, nkibikoresho byo kubanza gushyushya cyangwa gushyushya aho ukorera. Ubu buryo bugabanya ibikenerwa byo gushyushya byiyongera kandi bigabanya imikoreshereze rusange yingufu.

- Kugarura ubushyuhe bw’imyanda bishyigikira intego z’ibidukikije mu kugabanya ibyuka bihumanya ikirere.

- Gukoresha ubushyuhe bifasha ababikora kubahiriza ingufu zikomeye n’ibidukikije.

- Inzira nayo ituma ibiciro byo gukora bigabanuka, bigatuma granulators ishoramari ryubwenge.

Muguhuza ibiibintu bizigama ingufu, PE ntoya y'ibidukikije yashyizeho urwego rushya rwo gukora neza no kuramba mugutunganya plastike.

Inyungu zifatika n'ingaruka ku bidukikije

Gukoresha Ingufu Zikoresha

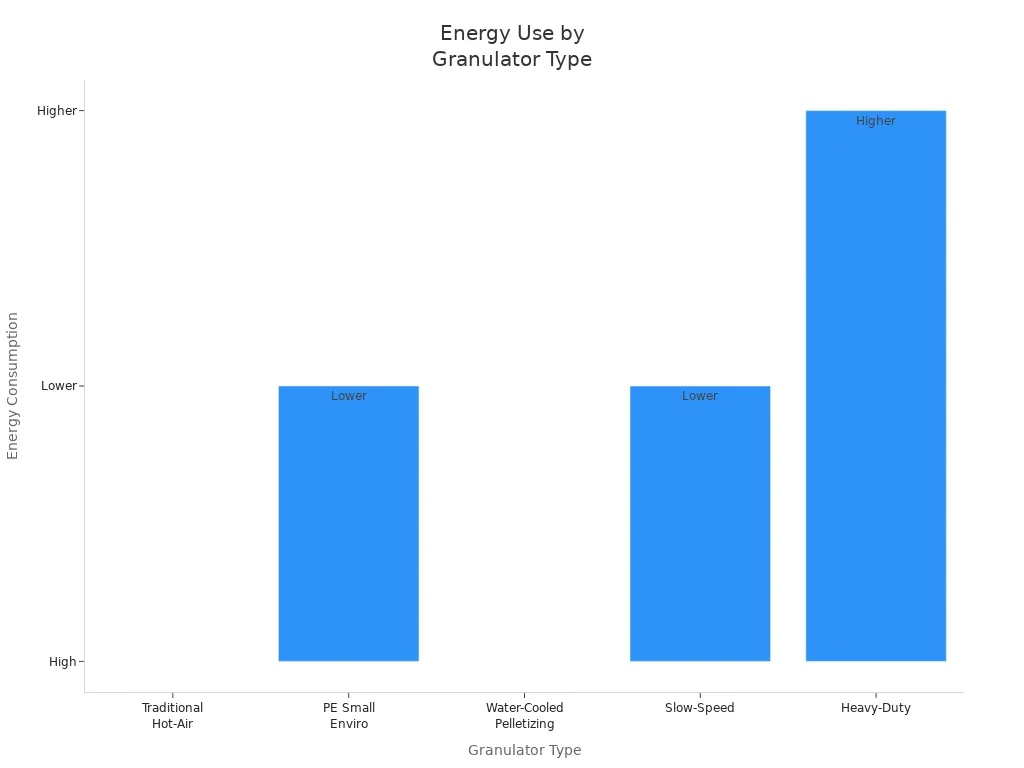

PE ntoya ya granulators yibidukikije igaragara neza kugirango ikoreshe ingufu nke. Imashini nyinshi gakondo, nka sisitemu ishyushye cyangwa amazi akonje, ikoresha amashanyarazi menshi kandi igatera umwanda mwinshi. Imbonerahamwe ikurikira irerekana uburyo ubwoko bwa granulator butandukanye bugereranya:

| Ubwoko bwa Granulator | Gukoresha Ingufu | Ingaruka ku bidukikije | Inyandiko y'ibikorwa |

|---|---|---|---|

| Gakondo-Umuyaga ushushe | Hejuru | Umwanda uhambaye | Kurenga 75% by'ibikoresho; ikeneye kuzamurwa |

| PE Ibidukikije bito byangiza ibidukikije | Hasi kubera gukonjesha ikirere no gukora-temp nke | Kugabanya ibyuka bihumanya bitewe no kuzigama ingufu | Koresha ibikoresho bishobora kuvugururwa no kugarura ubushyuhe |

| Sisitemu yo gukonjesha amazi | Hejuru (amazi n'amashanyarazi) | Umutwaro wibidukikije ukomoka kumazi | Ikirenge kinini, imikorere igoye |

| Buhoro buhoro Granulators | Hasi | Urusaku rwo hasi no kwambara | Nibyiza kubice bito, kuruhande-rwo-gukanda |

| Granulators Ziremereye | Hejuru | Hejuru kubera ibicuruzwa | Kubikoresho bikomeye; ingufu nke |

Gukonjesha ikirere, ubushyuhe buke bufasha aba granulator gukoresha ingufu nke. Basimbuka kandi intambwe yo kumisha, ikiza imbaraga nyinshi.

Kugabanya Ibirenge bya Carbone no kubahiriza

Izi mashini zifasha ibigo kugabanya ibirenge bya karubone. Bakoresha ingufu nke no gutunganya imyanda ya pulasitike aho, bivuze ko amakamyo make mumuhanda kandi umwanda muke.Imashini ntoya ya plastikekandi wirinde imyanda hanze y’imyanda. Muguhindura plastike ishaje mo pellet nshya, bagabanije gukenera ibikoresho bishya. Ubu ibigo byinshi byujuje amategeko akomeye y’ibidukikije tubikesha iri vugurura.

Icyitonderwa: Uruganda rukora imodoka rwo mu Budage rwazigamye toni 300 za plastiki nshya buri mwaka mugutunganya imyanda ya bumper hamwe na granulator nto.

Ikiguzi cyo kuzigama no gukora neza

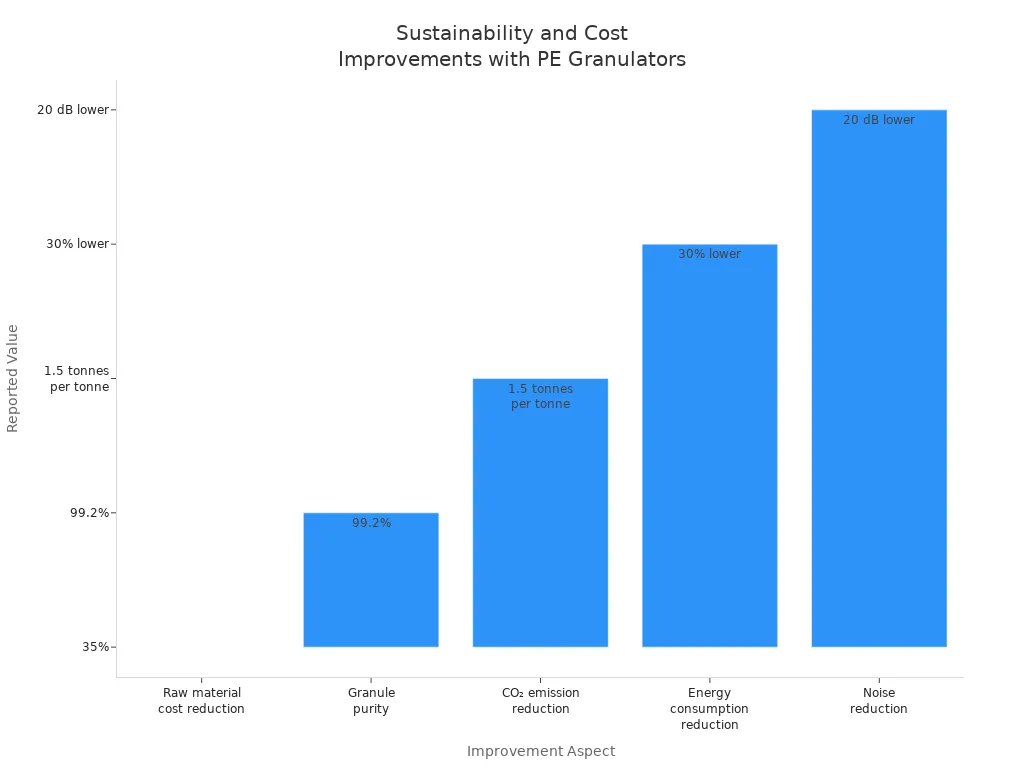

Ababikora babona kuzigama kwukuri hamwe na granulators. Moteri ikora neza hamwe na automatike yubwenge igabanya fagitire y'amashanyarazi. Akazi gaciriritse gasobanura amakosa make nigihe gito. Imbonerahamwe ikurikira irerekana uburyo auburyo bwubatswe butezimbere imikorere ninyungu:

| Icyiciro | Ibisobanuro | Ibikorwa by'ingenzi |

|---|---|---|

| Igenamigambi | Sobanura intego na KPI | Ishyirireho intego za SMART, utange ibikoresho |

| Kwicwa | Shyira mubikorwa impinduka env | Imishinga y'icyitegererezo, shiraho amahugurwa |

| Isuzuma | Kurikirana iterambere no gukusanya ibitekerezo | Koresha amakuru yisesengura, hindura nkuko bikenewe |

| Kwaguka | Gupima imyitozo igenda neza | Huza amasomo wize, uhugure |

Kugabanuka kwa 20% mugihe cyinzira irashobora kuganisha kumafaranga menshi. Kugarura ubushyuhe no gukoresha ingufu nke nabyo bigabanya ibiciro.

Ingano yuzuye hamwe nubushobozi bwumwanya

Igishushanyo mbonera cya granulators kibika umwanya w'agaciro. Amahugurwa mato hamwe n’ibigo bitunganya ibicuruzwa birashobora kubihuza bidahinduye imiterere. Abakoresha basanga byoroshye kubungabunga no gusukura, bivuze ko igihe gito cyo hasi. Modular igizwe ishyigikira gufunga-gusubiramo, gukora inzira yose neza kandi irambye.

Impanuro: Ikirenge gito gisobanura icyumba kinini kubindi bikoresho cyangwa kwaguka ejo hazaza.

PE ntoya y’ibidukikije yashyizeho urwego rushya rwo gukoresha ingufu muri 2025. Ababikora babona inyungu nyazo:

- Ibiciro biri hasi hamwe n imyanda mike

- Igipimo cyo hejuru cyo gutunganya

- Inkunga yintego zirambye

- Kwishura byihuse no kubahiriza bikomeye

Ibibazo

Nigute PE ntoya ya granulator ibidukikije ifasha kuzigama ingufu?

Granulator ikoresha moteri ikora neza kandi ikora neza. Ibi biranga kugabanya gukoresha amashanyarazi no gukomeza umusaruro uhamye.

Impanuro: Igenzura ryubwenge reka abashoramari bahindure igenamigambi byihuse kugirango babike byinshi.

Amahugurwa mato arashobora gukoresha iyi granulator?

Yego, barashobora. Ingano yoroheje ihuye n'umwanya muto. Abakoresha basanga byoroshye gushiraho no kubungabunga.

- Ihuza imirongo mito yo gukora

- Biroroshye gukora

Nibihe bikoresho PE ishobora gutunganya ibidukikije bito?

IkemuraPE hamwe nibindi bikoresho bya plastiki. Imashini ikora neza mugutunganya imyanda ya plastike muri pellet nshya.

| Ubwoko bwibikoresho | Bikwiranye na Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| PVC | ✅ |

Igihe cyo kohereza: Kanama-14-2025